- Home

- Blog

- News

- Basics

- Sources

- Agencies, Regulatory & Organisations

- CERSI Excipients Browser

- Excipient Report

- Excipient DMF List

- EXCiPACT Certified Companies

- Excipient Documentation

- Excipient EINECS Numbers

- Excipient E-Numbers

- FDA Inactive Ingredient List

- FDA GRAS Substances (SCOGS) Database

- IPEC Americas

- USP - U.S. Pharmacopeia

- Definitions

- Whitepapers / Publications

- Supplier

- Services

- Media

- Events

- 1st pharmaexcipients Poster Award

- Event Calendar

- Events featured by pharma-excipients

- 4th Annual Formulation & Drug Delivery Congress

- DDF Summit

- ExcipientFest Americas

- ExcipientFest Asia

- Global CompliancePanel

- International Conference and Exhibition on Pharmaceutics & Novel Drug Delivery Systems

- Formulation & Drug Delivery USA Congress

- Laboratory Medicine 2018

- Making Pharmaceuticals Europe

- Making Pharmaceuticals Exhibition

- Pharma Integrates

- PharmaExcipients China @CPhI China

- TTC Technology Training Center

- Jobs

- Online Sourcing

- Contact

07. July 2018

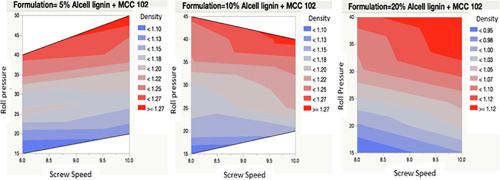

In this study, a process map was developed in an effort to improve the understanding of dry granulation of pharmaceutical excipients by roll compaction process, and to implement the quality-by-design (QbD) approach. Through development of the process map, a correlation was made between the critical process parameters (roll pressure, screw speed), and critical quality attributes (density of ribbons and granule size). This method reduces development time, quantity of materials required and cost....

28. November 2017

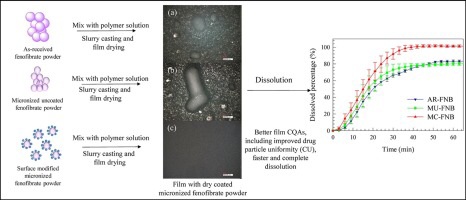

Recent work has established polymer strip films as a robust platform for delivery of poorly water-soluble drugs via slurry casting, in particular using stable drug nanosuspensions. Here, a simpler, robust method to directly incorporate dry micronized poorly water-soluble drug, fenofibrate (FNB), is introduced. As a major novelty, simultaneous surface modification using hydrophilic silica along with micronization was done using fluid energy mill (FEM) in order to reduce FNB hydrophobicity and...

05. July 2017

The current regulatory environment based on the ICH guidelines encourages a systematic and science-based approach in the pharmaceutical development, required by the “Quality by design” concept.

06. March 2017

Abstract We applied the Quality by Design (QbD) approach to the development of poly(lactic-co-glycolic acid) (PLGA) nanoparticle formulations encapsulating triamcinolone acetonide, and the critical process parameters (CPPs) were identified to clarify the correlations between critical quality attributes and CPPs. Quality risk management was performed by using an Ishikawa diagram and experiments with a fractional factorial design (ANOVA). The CPPs for particle size were PLGA concentration and...

11. January 2017

Abstract With the implementation of quality by design (QbD), critical attributes of raw material (drug substance and excipients) are of significantly importance in pharmaceutical manufacturing process. It is desirable for the quality control of critical material attributes (CMAs) of excipients to ensure the quality of end product. This paper explored the feasibility of an at-line method for the quantitative analysis of hydroxypropoxy group in hydroxypropyl methylcellulose (HPMC) with near...

04. August 2016

Objectives: To develop orodispersible films (ODF) based on hydrophobic polymers with higher stability to ordinary environmental humidity conditions without compromising their fast disintegration time. Methods: A quality by design approach was applied to screen three different formulations each one based on a different hydrophobic polymer: polyvinyl acetate, methacrylate-based copolymer and shellac. The screening formulations were characterized regarding their mechanical properties, residual...

04. July 2016

Context: Orodispersible films have gained increasing relevance as a novel dosage form. Associated to their particular processing and multicomponent composition, there are a vast number of reasons to establish helpful development guidance, gathering simultaneously the recent pharmaceutical regulatory trends. Objective: This study aimed characterize marketed orodispersible films in order to provide essential information about a clear definition of product critical quality attributes (CQAs)....

07. September 2015

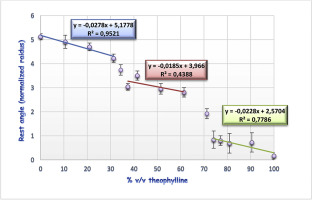

There are many factors influencing the drug release behaviour from a pharmaceutical formulation as the particle size of the drug and excipient, porosity of the system or geometrical phase transitions of the components. Therefore, the choice of the adequate excipient to achieve a specific drug release profile is mainly based on the experience and the trial and error method. Taking into account the directives towards the application of the “Quality by Design” approach, in this study the...

08. August 2015

There are many factors influencing the drug release behaviour from a pharmaceutical formulation as the particle size of the drug and excipient, porosity of the system or geometrical phase transitions of the components. Therefore, the choice of the adequate excipient to achieve a specific drug release profile is mainly based on the experience and the trial and error method. More

05. August 2015