- Home

- Blog

- News

- Basics

- Sources

- Agencies, Regulatory & Organisations

- CERSI Excipients Browser

- Excipient Report

- Excipient DMF List

- EXCiPACT Certified Companies

- Excipient Documentation

- Excipient EINECS Numbers

- Excipient E-Numbers

- FDA Inactive Ingredient List

- FDA GRAS Substances (SCOGS) Database

- IPEC Americas

- USP - U.S. Pharmacopeia

- Definitions

- Whitepapers / Publications

- Supplier

- Services

- Media

- Events

- 1st pharmaexcipients Poster Award

- Event Calendar

- Events featured by pharma-excipients

- 4th Annual Formulation & Drug Delivery Congress

- DDF Summit

- ExcipientFest Americas

- ExcipientFest Asia

- Global CompliancePanel

- International Conference and Exhibition on Pharmaceutics & Novel Drug Delivery Systems

- Formulation & Drug Delivery USA Congress

- Laboratory Medicine 2018

- Making Pharmaceuticals Europe

- Making Pharmaceuticals Exhibition

- Pharma Integrates

- PharmaExcipients China @CPhI China

- TTC Technology Training Center

- Jobs

- Online Sourcing

- Contact

16. August 2018

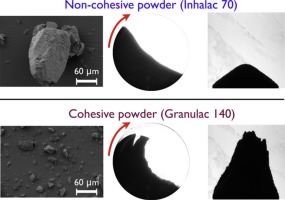

The purpose of this work is to demonstrate a process for the alteration of the shape of needle shaped crystals of an active pharmaceutical ingredient (API) using a combination of wet milling and temperature cycling. The effect upon powder handling metrics of the shape alteration approach was quantified and the impact upon a subsequent roller compaction process step demonstrated. Methods Particle shape was altered through a combination of wet milling and temperature cycling. Image analysis was...

21. July 2018

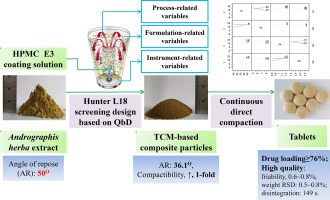

The Andrographis herba extract (AHE), a traditional Chinese medicine (TCM), was developed to directly compactible powders by fluid bed coating with 6% to 12% hydroxypropyl methylcellulose (HPMC). The process-, instrument-, and formulation-related variables of the coating process were simultaneously optimized with the Hunter L18 screening design. Yield (Y1), compactibility (Y2), and angle of repose (Y3) were measured as the responses. The optimized variables were 50 °C for inlet air...

26. May 2018

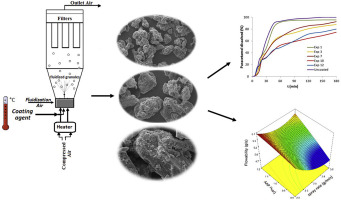

Hot-melt coating is a novel and cost-effective solvent-free coating technique. Commonly used excipients for hot-melt coating are lipid substances. In this work, modified fluidized-bed system was applied for coating, and additional components were used to melt and convey the excipient to the fluidized-bed apparatus. Granules containing 20% (w/w) paracetamol were coated with Precirol® ATO 5 at 9.1% (w/w) coating level. The aims of this study were to define a relationship between the three...

26. April 2018

Are you a manufacturer of raw materials for the food, nutraceutical or pharmaceutical industry and interested to increase your product performance or functionality? Are topics like Dust free Solubility Protection Taste masking Targeted release Particle size Flowability relevant to you or for the life cycle management of your product? Then come to speak with the experts from IPC Process Center @Vitafoods Geneva Stand T167 - May 15-17, 2018. If not attending just drop us an email. Further...

30. January 2018

Continuous Manufacturing Technology continues to gain importance in pharmaceutical manufacturing.

Although traditional processes like direct compression, roller compaction, or wet granulation are used within the continuous lines, the requirement for ingredients may differ from traditional batch processing.

29. November 2017

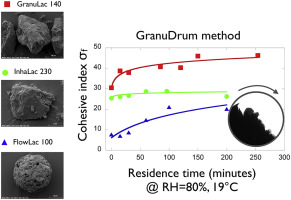

Purpose Characterisation of powder flow is important for pharmaceutical processing and manufacturing. This work aims at a better understanding of how fractal particle and bulk properties affect the static and dynamic flow of excipients. Methods Traditional methods of flowability testing, e.g. the angle of repose or the flow through an orifice, were complemented by avalanching in a rotational drum. Dynamic image analysis provided a fractal contour line dimension of the powder bulk in the drum...

25. November 2017

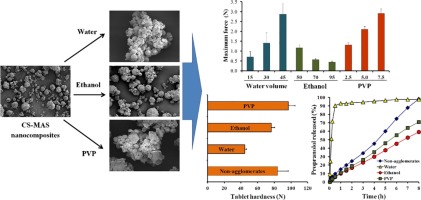

Exfoliated nanocomposites of chitosan-magnesium aluminum silicate (CS-MAS) particles are characterized by good compressibility but poor flowability. Thus, the aims of this study were to investigate agglomerates of CS-MAS nano composites prepared using the agglomerating agents water, ethanol, or polyvinylpyrrolidone (PVP) for flowability enhancement and to evaluate the agglomerates obtained as direct compression fillers for tablets.

24. August 2017

The flowing properties of 10 lactose powders commonly used in pharmaceutical industries have been analyzed with three recently improved measurement methods. The first method is based on the heap shape measurement.

23. August 2017

Moisture is known to affect the flowing properties of powders. However, the quantification and the understanding of the observed effects are far to be obvious.

05. April 2017

Abstract We investigated the effectiveness of using Carr’s flowability index (FI) and practical angle of internal friction (Φ) as indexes for setting the target Mg-St mixing time needed for preparing tablets with the target physical properties. We used FI as a measure of flowability under non-loaded conditions, and Φ as a measure of flowability under loaded conditions for pharmaceutical powders undergoing direct compression with varying concentrations of Mg-St and mixing times. We evaluated...