- Home

- Blog

- News

- Basics

- Sources

- Agencies, Regulatory & Organisations

- CERSI Excipients Browser

- Excipient Report

- Excipient DMF List

- EXCiPACT Certified Companies

- Excipient Documentation

- Excipient EINECS Numbers

- Excipient E-Numbers

- FDA Inactive Ingredient List

- FDA GRAS Substances (SCOGS) Database

- IPEC Americas

- USP - U.S. Pharmacopeia

- Definitions

- Whitepapers / Publications

- Supplier

- Services

- Media

- Events

- 1st pharmaexcipients Poster Award

- Event Calendar

- Events featured by pharma-excipients

- 4th Annual Formulation & Drug Delivery Congress

- DDF Summit

- ExcipientFest Americas

- ExcipientFest Asia

- Global CompliancePanel

- International Conference and Exhibition on Pharmaceutics & Novel Drug Delivery Systems

- Formulation & Drug Delivery USA Congress

- Laboratory Medicine 2018

- Making Pharmaceuticals Europe

- Making Pharmaceuticals Exhibition

- Pharma Integrates

- PharmaExcipients China @CPhI China

- TTC Technology Training Center

- Jobs

- Online Sourcing

- Contact

05. April 2018

Fused deposition modeling 3D printing (3DP) has a potential to change how we envision manufacturing in the pharmaceutical industry. A more common utilization for FDM is to build upon existing hot melt extrusion technology where the drug is dispersed in the polymer matrix. However, reliable manufacturing of drug-containing FDM filaments remains a challenge along with the limitation of active ingredients which can sustain the processing risks involved in the HME process. To circumvent this...

11. January 2018

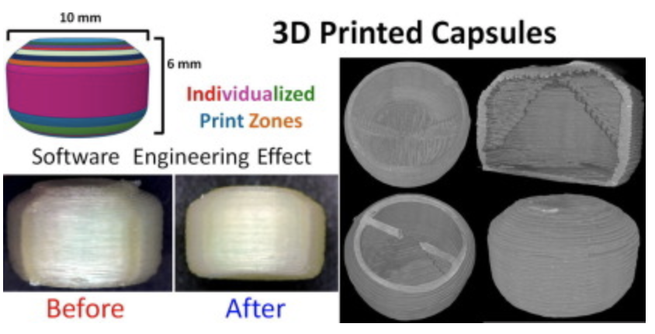

The object of this study is to prepare and evaluate tablets with predesigned internal scaffold structure using 3D printing to achieve sustained drug release. Model drug (ibuprofen) and sustained release material (ethyl cellulose), together with other excipients, were firstly mixed and extruded into filaments by hot melt extrusion. Then these obtained filaments were printed into tablets by fused deposition modeling.

04. December 2017

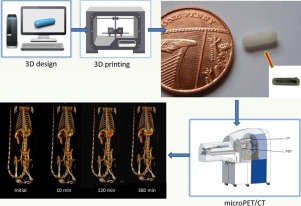

Fused deposition modelling (FDM) 3D printing (3DP) is a revolutionary technology with the potential to transform drug product design in both the pre-clinical and clinical arena. The objective of this pilot study was to explore the intestinal behaviour of four different polymer-based devices fabricated using FDM 3DP technology in rats.

27. October 2017

The primary aim of this study was to identify pharmaceutically acceptable amorphous polymers for producing 3D printed tablets of a model drug, haloperidol, for rapid release by fused deposition modeling (FDM).

19. June 2017

3D printing has been recently employed in the design and fabrication of medicine, aiming to improve their properties and release behavior. In the current work an oral solid dosage form was designed by Fused Deposition Modeling (FDM), using a custom built filament comprised of a water soluble polymer polyvinyl alcohol (PVA), mannitol and hydrochlorothiazide (HCTZ) as model drug and further co-formulated via Hot-Melt Extrusion (HME).