- Home

- Blog

- News

- Basics

- Sources

- Agencies, Regulatory & Organisations

- CERSI Excipients Browser

- Excipient Report

- Excipient DMF List

- EXCiPACT Certified Companies

- Excipient Documentation

- Excipient EINECS Numbers

- Excipient E-Numbers

- FDA Inactive Ingredient List

- FDA GRAS Substances (SCOGS) Database

- IPEC Americas

- USP - U.S. Pharmacopeia

- Definitions

- Whitepapers / Publications

- Supplier

- Services

- Media

- Events

- 1st pharmaexcipients Poster Award

- Event Calendar

- Events featured by pharma-excipients

- 4th Annual Formulation & Drug Delivery Congress

- DDF Summit

- ExcipientFest Americas

- ExcipientFest Asia

- Global CompliancePanel

- International Conference and Exhibition on Pharmaceutics & Novel Drug Delivery Systems

- Formulation & Drug Delivery USA Congress

- Laboratory Medicine 2018

- Making Pharmaceuticals Europe

- Making Pharmaceuticals Exhibition

- Pharma Integrates

- PharmaExcipients China @CPhI China

- TTC Technology Training Center

- Jobs

- Online Sourcing

- Contact

20. September 2018

The comparison of spray drying versus hot melt extrusion (HME) in order to formulate amorphous solid dispersions has been widely studied. However, to the best of our knowledge, the use of both techniques to form cocrystals within a carrier excipient has not previously been compared. The combination of ibuprofen (IBU) and isonicotinamide (INA) in a 1:1 molar ratio was used as a model cocrystal. A range of pharmaceutical excipients was selected for processing - mannitol, xylitol, Soluplus and PVP...

20. February 2018

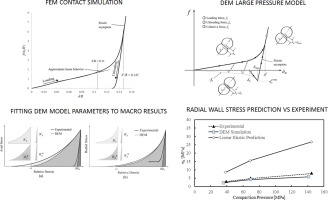

Abstract The mechanical behavior of powders during die compaction was investigated using the discrete element method (DEM), in which powders are modeled as discrete particles with elastoplastic material behavior. A new adhesive elastoplastic contact model that describes the force displacement behavior of contacting particles subjected to high confining conditions was introduced and implemented in DEM simulations of die compaction and uniaxial tension. The objectives of these simulations were:...

27. September 2017

Many future drug products will be based on innovative manufacturing solutions, which will increase the need for a thorough understanding of the interplay between drug material properties and processability. In this study, hot melt extrusion of a drug-drug mixture with minimal amount of polymeric excipient was investigated.

05. July 2017

n this poster, Merck evaluate a pharmaceutical grade polyvinyl alcohol (PVA) as the matrix polymer for HME application…

22. February 2017

Hot Melt Extrusion (HME) technology is a widely used for manufacturing process in the plastic and pharmaceutical industries and is an efficient and simple for the production of a solid dispersion. This technique is an environmental friendly, continuous process that does not use solvents. It is time and cost efficient and can be easily scaled up. In addition, HME may be used in conjunction with other technologies to effectively increase the solubility and dissolution rate of poorly water-soluble...

13. August 2016

Abstract Purpose The fabrication of ready-to-use immediate release tablets via 3D printing provides a powerful tool to on-demand individualization of dosage form. This work aims to adapt a widely used pharmaceutical grade polymer, polyvinylpyrrolidone (PVP), for instant on-demand production of immediate release tablets via FDM 3D printing. Methods Dipyridamole or theophylline loaded filaments were produced via processing a physical mixture of API (10%) and PVP in the presence of plasticizer...

05. July 2016

This technical paper studies the impact of extrusion process parameters on the performance of solid dispersions of Ritonavir, a poorly soluble antiretroviral drug, and AFFINISOL (TM) HPMC HME, a new grade of HPMC designed for hot melt extrusion. The formulation with a fixed drug: polymer ratio was extruded at different processing conditions exploring the variables of feed rate, screw speed and temperature for their impact on drug degradation, its physical state and dissolution performance of...

18. February 2016

Purpose: Introduction to hot melt co-extrusion for utilization as a drug delivery method. Influence of process parameters on final drug product quality. Application of Raman imaging microscopy as a analytical tool for quality control of the co-extrudate. Methods: Co-extrusion with a newly designed co-extrusion die and a pharmaceutical relevant polymer/active formulation. Chemical mapping with Raman microscopy to provide evidence on extrudate integrity and absence of drug migration. Results: The...