- Home

- Blog

- News

- Basics

- Sources

- Agencies, Regulatory & Organisations

- CERSI Excipients Browser

- Excipient Report

- Excipient DMF List

- EXCiPACT Certified Companies

- Excipient Documentation

- Excipient EINECS Numbers

- Excipient E-Numbers

- FDA Inactive Ingredient List

- FDA GRAS Substances (SCOGS) Database

- IPEC Americas

- USP - U.S. Pharmacopeia

- Definitions

- Whitepapers / Publications

- Supplier

- Services

- Media

- Events

- 1st pharmaexcipients Poster Award

- Event Calendar

- Events featured by pharma-excipients

- 4th Annual Formulation & Drug Delivery Congress

- DDF Summit

- ExcipientFest Americas

- ExcipientFest Asia

- Global CompliancePanel

- International Conference and Exhibition on Pharmaceutics & Novel Drug Delivery Systems

- Formulation & Drug Delivery USA Congress

- Laboratory Medicine 2018

- Making Pharmaceuticals Europe

- Making Pharmaceuticals Exhibition

- Pharma Integrates

- PharmaExcipients China @CPhI China

- TTC Technology Training Center

- Jobs

- Online Sourcing

- Contact

20. September 2018

The comparison of spray drying versus hot melt extrusion (HME) in order to formulate amorphous solid dispersions has been widely studied. However, to the best of our knowledge, the use of both techniques to form cocrystals within a carrier excipient has not previously been compared. The combination of ibuprofen (IBU) and isonicotinamide (INA) in a 1:1 molar ratio was used as a model cocrystal. A range of pharmaceutical excipients was selected for processing - mannitol, xylitol, Soluplus and PVP...

05. April 2018

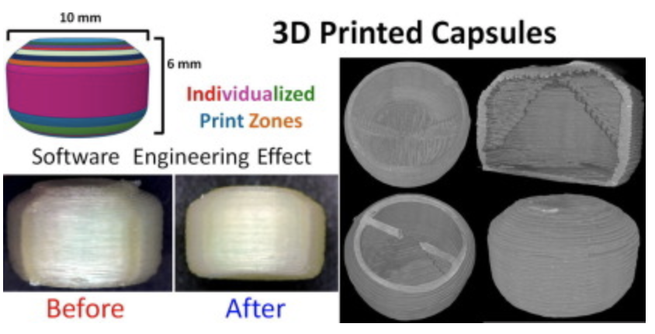

Fused deposition modeling 3D printing (3DP) has a potential to change how we envision manufacturing in the pharmaceutical industry. A more common utilization for FDM is to build upon existing hot melt extrusion technology where the drug is dispersed in the polymer matrix. However, reliable manufacturing of drug-containing FDM filaments remains a challenge along with the limitation of active ingredients which can sustain the processing risks involved in the HME process. To circumvent this...

31. March 2018

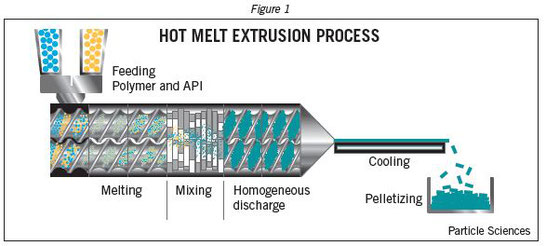

Just found this chapter of the 2nd Edition of "Pharmaceutical Extrusion Technology" which can be of interest in the field of continuous manufacturing. Hot melt extrusion (HME) is a continuous process operation that has been successfully applied to the manufacture of quality drug products over the last decade [1–4]. 54HME achieves the molecular mixing of active pharmaceutical ingredients (API) and excipients at temperatures above their glass transition temperatures (T g) and/or melting...

22. February 2018

Hot melt extrusion has gained considerable attention as a novel technique for taste masking of bitter APIs. The aim of this study was to investigate whether hot melt extrusion could be used to develop taste masked formulations of isoniazid and also to evaluate and correlate different taste assessment methods Two polymers with different physico-chemical properties, Soluplus and Eudragit E-PO were chosen as carriers for the drug. Eudragit E-PO has already been widely used for taste masking due to...

11. January 2018

The object of this study is to prepare and evaluate tablets with predesigned internal scaffold structure using 3D printing to achieve sustained drug release. Model drug (ibuprofen) and sustained release material (ethyl cellulose), together with other excipients, were firstly mixed and extruded into filaments by hot melt extrusion. Then these obtained filaments were printed into tablets by fused deposition modeling.

15. November 2017

The purpose of this study was to explore poly(vinylpyrrolidone-co-vinyl acetate) (PVP VA64) as a novel release-modifier to tailor the drug release from ethylcellulose (EC)-based mini-matrices prepared via hot melt extrusion (HME). Quetiapine fumarate (QF) was selected as model drug. QF/EC/PVP VA64 mini-matrices were extruded with 30% drug loading.

13. November 2017

Amorphous solid dispersions (SDs) are considered as one of the most effective strategies for the formulation of poorly water-soluble compounds. The active compound is dispersed in an inert carrier composed of a polymer and active excipients. Since the drug is amorphous, there is typically an increase in apparent solubility as well as dissolution rate. Various methods are employed for manufacturing of SDs, nevertheless, hot-melt extrusion (HME) has become one of the most common process techniques

15. August 2017

This study investigates the stability of typically complex multi-component hydrophilic solid dispersions that could be used in a clinical application.

28. July 2017

The objective of the current study was to develop an amorphous solid dispersion for a high melting point compound, griseofulvin (GRF), with an enhanced solubility and a controlled release pattern utilizing hot melt extrusion (HME) technology.

09. July 2017

Hot melt extrusion has gained considerable attention as a novel technique for taste masking of bitter APIs. The aim of this study was to investigate whether hot melt extrusion could be used to develop taste masked formulations of isoniazid and also to evaluate and correlate different taste assessment methods Two polymers with different physico-chemical properties, Soluplus and Eudragit E-PO were chosen as carriers for the drug.