- Home

- Blog

- News

- Basics

- Sources

- Agencies, Regulatory & Organisations

- CERSI Excipients Browser

- Excipient Report

- Excipient DMF List

- EXCiPACT Certified Companies

- Excipient Documentation

- Excipient EINECS Numbers

- Excipient E-Numbers

- FDA Inactive Ingredient List

- FDA GRAS Substances (SCOGS) Database

- IPEC Americas

- USP - U.S. Pharmacopeia

- Definitions

- Whitepapers / Publications

- Supplier

- Services

- Media

- Events

- 1st pharmaexcipients Poster Award

- Event Calendar

- Events featured by pharma-excipients

- 4th Annual Formulation & Drug Delivery Congress

- DDF Summit

- ExcipientFest Americas

- ExcipientFest Asia

- Global CompliancePanel

- International Conference and Exhibition on Pharmaceutics & Novel Drug Delivery Systems

- Formulation & Drug Delivery USA Congress

- Laboratory Medicine 2018

- Making Pharmaceuticals Europe

- Making Pharmaceuticals Exhibition

- Pharma Integrates

- PharmaExcipients China @CPhI China

- TTC Technology Training Center

- Jobs

- Online Sourcing

- Contact

06. August 2018

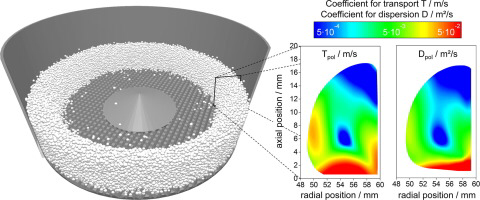

Spherical pellets for pharmaceutical applications are widely produced by an extrusion-spheronization process. To achieve an equal, spherical pellet shape with a spheronization process, it is crucial that all pellets are exposed to similar stress conditions. However, in a spheronizer the pellets close to the friction plate are subjected to much higher stresses than pellets at the top of the torus, resulting in a strongly inhomogeneous stress distribution within the particle bed. Therefore, the...

05. March 2018

This study presents a framework for process and product development on a continuous direct compression manufacturing platform. A challenging sustained release formulation with high content of a poorly flowing low density drug was selected. Two HPMC grades were evaluated as matrix former: standard Methocel CR and directly compressible Methocel DC2. The feeding behavior of each formulation component was investigated by deriving feed factor profiles.

13. November 2017

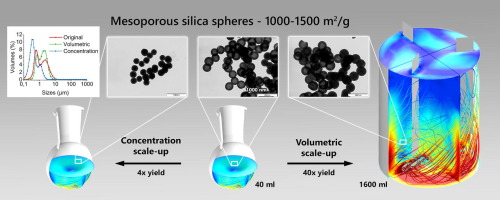

Despite the wide application interest in mesoporous silica micro- and nano-particles and a number of synthesis routes reported in the literature, the question of chemical engineering scale-up of the synthetic routes has rarely been addressed.

06. November 2017

Many efforts have been made in the past to understand the function of lactose fines which are given as a ternary component to carrier-based dry powder inhaler formulations. It is undisputed that fines can significantly improve the performance of such formulations, but choosing the right amount of fines is a crucial point, because too high concentrations can have negative effects on the dispersion performance

26. September 2017

The lubrication effects of two mixing systems were studied. Shear without MgSt significantly increased blend cohesion.

The effect of shear rate during lubrication was not significant.

The correlations between two mixing systems were established

21. June 2017

Powder blend homogeneity is a critical attribute in formulation development of low dose and potent active pharmaceutical ingredients (API) yet a complex process with multiple contributing factors. Excipient characteristics play key role in efficient blending process and final product quality. In this work the effect of excipient type and properties, blending technique and processing time on content uniformity was investigated.

21. April 2017

Abstract The potential of fine excipient materials to improve the performance of carrier-based dry powder inhalation mixtures is well acknowledged. The mechanisms underlying this potential are, however, open to question till date. Elaborate understanding of these mechanisms is a requisite for rational rather than empirical development of ternary dry powder inhalation mixtures. While effects of fine excipient materials on drug adhesion to and detachment from surfaces of carrier particle have...

06. February 2017

Abstract The purpose of this work was to assess the impact of continuous mixing on tablet critical quality attributes (CQAs) manufactured using a continuous, direct compression process. A nine run design of experiments (DoE) that bracketed the range of commercially relevant mixer speeds, mixer orientations, and mass flow rates was executed using a formulation containing a cohesive drug substance at relatively low drug load. Drug substance dispensed concentration using loss-in-weight feeders was...

24. August 2016

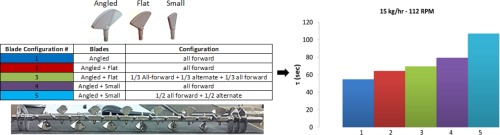

Abstract The present study summarizes the experimental characterization of a new continuous powder mixer (GCG-70 by Glatt®) using common pharmaceutical ingredients. The powder hold-up and residence time distribution were used to characterize the bulk behavior of the mixer as a function of impeller rotational speed, total throughput (mass flow rate) and blade configuration. The relative standard deviation (RSD), calculated from samples taken at the outlet of the blender, was used to...

27. July 2016

Abstract The development of process analytical technologies (PAT) can improve the efficiency and product quality during pharmaceutical manufacturing. The objective of the current research was to investigate the potential application of passive acoustic emission monitoring to detect changes due to lubricant addition and its dispersal in a V-blender. Trials were conducted with sugar spheres and two placebo formulations of pharmaceutical granules in a V-blender. Vibrations from acoustic emissions...