- Home

- Blog

- News

- Basics

- Sources

- Agencies, Regulatory & Organisations

- CERSI Excipients Browser

- Excipient Report

- Excipient DMF List

- EXCiPACT Certified Companies

- Excipient Documentation

- Excipient EINECS Numbers

- Excipient E-Numbers

- FDA Inactive Ingredient List

- FDA GRAS Substances (SCOGS) Database

- IPEC Americas

- USP - U.S. Pharmacopeia

- Definitions

- Whitepapers / Publications

- Supplier

- Services

- Media

- Events

- 1st pharmaexcipients Poster Award

- Event Calendar

- Events featured by pharma-excipients

- 4th Annual Formulation & Drug Delivery Congress

- DDF Summit

- ExcipientFest Americas

- ExcipientFest Asia

- Global CompliancePanel

- International Conference and Exhibition on Pharmaceutics & Novel Drug Delivery Systems

- Formulation & Drug Delivery USA Congress

- Laboratory Medicine 2018

- Making Pharmaceuticals Europe

- Making Pharmaceuticals Exhibition

- Pharma Integrates

- PharmaExcipients China @CPhI China

- TTC Technology Training Center

- Jobs

- Online Sourcing

- Contact

06. August 2018

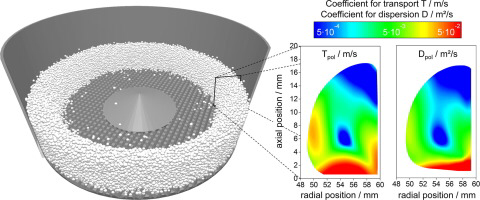

Spherical pellets for pharmaceutical applications are widely produced by an extrusion-spheronization process. To achieve an equal, spherical pellet shape with a spheronization process, it is crucial that all pellets are exposed to similar stress conditions. However, in a spheronizer the pellets close to the friction plate are subjected to much higher stresses than pellets at the top of the torus, resulting in a strongly inhomogeneous stress distribution within the particle bed. Therefore, the...

06. February 2017

Abstract The aim of this study was to develop mucoadhesive pellets on a thiolated pectin base using the extrusion-spheronization technique. Thiolation of pectin was performed by esterification with thioglycolic acid. The molecular weight and thiol group content of the pectins were determined. Pellets containing pectin, microcrystalline cellulose and ketoprofen were prepared and their mucoadhesive properties were evaluated through a wash-off test using porcine intestinal mucosa. The in vitro...

20. November 2016

Abstract In this study a multiparticulate matrix system was produced, containing two different APIs: enalapril-maleate and hydrochlorothiazide. The critical control points of the process were investigated by means of factorial design. Besides the generally used microcrystalline cellulose, ethylcellulose was used as matrix former to achieve modified drug release ensured by diffusion. The matrix pellets were made by extrusion-spheronization using a twin-screw extruder. Some pellet properties...

24. August 2016

ABSTRACT In pharmaceutical industries, pellets are multiparticulate dosage form which was formed by the agglomeration of fine powdered excipient and drugs together that leads to the formation of small free flowing spherical or semi spherical particles. This technique is called as pelletization process. Pellets are typically varied between 500-1500 μm in size for pharmaceutical applications. It is of great interest over other similar techniques due to its uniformity of dose, less susceptibility...

04. July 2016

Abstract We aimed to elucidate the mechanism of the spheronization of pharmaceutical material crystals through extremely high shearing force using a mechanical powder processor, which produces spherical crystals without a solvent. The spheronization of theophylline, acetaminophen, clarithromycin, ascorbic acid and lactose was investigated, and the relationship between the spheronization mechanism and material characteristics was also examined. Theophylline and ascorbic acid crystals were...

14. June 2016

Abstract Lansoprazole degrades rapidly in an aqueous solution at low pH values. Degradation rate increases at pH values below 4 .The aim of this study was development of enteric coated pellets containing Lansoprazole by an extrusion/ spheronization technique. Eight different formulations based on lactose and six different formulations based on mannitol, consisting of different portions of other excipients including sucrose, hydroxy propyl methyl cellulose, magnesium carbonate, and sodium lauryl...

03. May 2016

Taste-masked properties of micropellets based on hard fat and/or solid lipid mixtures (prepared by solvent-free cold extrusion/spheronization), containing metformin hydrochloride were investigated. An in-line and an on-line drug release profile evaluation of the pellets was performed and further correlated with an electronic tongue investigation. The pellets based on more than 30% of lipid binders showed metformin HCl releases below 10% after 30 s of dissolution. Micropellets based on 20 and...

28. April 2016

The search for excipients to replace microcrystalline cellulose (MCC) in the production of pellets by extrusion-spheronization in cases of drug incompatibility or the lack of pellet matrix disintegration forms the basis of this study. A combination of к-carrageenan as a spheronization aid, chitosan as a diluent, and Carbopol® 974P as a binder in the production of pellets containing no MCC has been investigated using acetaminophen as a model drug. More

20. February 2016

Extrusion spheronization is the widely used method by which the pellets are formulated. Pellets have certain advantages in the development of modified release dosage forms, Because of their regular shape and size they are suitable for coating and encapsulation processes, In addition, pellets may sometimes improve the bioavailability, reduce the risk of dose dumping and decrease local irritations in the gastrointestinal tract. Ideal pelletizing aid for this process is MCC as it possesses...

18. January 2016

The objective was to formulate itopride HCl (ITP) extended release matrix-coated pellets by extrusion–spheronization and to investigate the influence of concentration and viscosity grade of different polymers on release of a highly water soluble drug. The matrix pellet formulations consisted of polymers (10–30%) like hydroxypropyl methylcellulose (HPMC K4M, K15M, and K100M), ethyl cellulose (EC-7 cps), microcrystalline cellulose (10–30%) and a fixed quantity of lactose (10%). More