- Home

- Blog

- News

- Basics

- Sources

- Agencies, Regulatory & Organisations

- CERSI Excipients Browser

- Excipient Report

- Excipient DMF List

- EXCiPACT Certified Companies

- Excipient Documentation

- Excipient EINECS Numbers

- Excipient E-Numbers

- FDA Inactive Ingredient List

- FDA GRAS Substances (SCOGS) Database

- IPEC Americas

- USP - U.S. Pharmacopeia

- Definitions

- Whitepapers / Publications

- Supplier

- Services

- Media

- Events

- 1st pharmaexcipients Poster Award

- Event Calendar

- Events featured by pharma-excipients

- 4th Annual Formulation & Drug Delivery Congress

- DDF Summit

- ExcipientFest Americas

- ExcipientFest Asia

- Global CompliancePanel

- International Conference and Exhibition on Pharmaceutics & Novel Drug Delivery Systems

- Formulation & Drug Delivery USA Congress

- Laboratory Medicine 2018

- Making Pharmaceuticals Europe

- Making Pharmaceuticals Exhibition

- Pharma Integrates

- PharmaExcipients China @CPhI China

- TTC Technology Training Center

- Jobs

- Online Sourcing

- Contact

31. August 2018

Sugars and sweeteners are common ingredients in foods and also in pharmaceutical industries. They are soluble and sticky ingredients and their processing in granulators may be difficult since they can easily adhere to mixer walls or leadto uncontrolled granule growth. The purpose of this research was to evaluate the feasibility of the high shear wet granulation process and to find the optimal amount of binder by studying the granulation performances of four sugars: mannitol, sorbitol, xylitol...

10. August 2018

Sticking and picking during tablet manufacture has received increasing interest recently, as it causes tablet defects, downtime in manufacturing, and yield losses. The capricious nature of the problem means that it can appear at any stage of the development cycle, even when it has been deemed as low risk by models, tests, and previous experience. In many cases, the problem manifests when transferring the process from one manufacturing site to another. Site transfers are more common now than in...

04. October 2017

In this study, Metrics Contract Services was tasked with a complex re-formulation project. Briefly, the free-acid form of an API, Compound XY, was previously manufactured as 5-mg, 10-mg, and 25-mg strength tablets using direct compression process.

09. August 2017

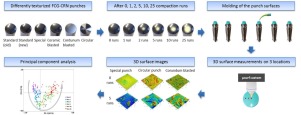

The surface quality of tablets is strongly related to the surface quality of the tablet punch. Therefore, regular control of the punch surfaces is needed to determine the surface properties, the wear status and sticking tendency of the punches

23. May 2017

Summary Poor lubrication results in picking and sticking problems during production. These are one of the most common causes of tablet defects which result in slow running of the tablet press and reduced output. High ejection stress (>5 MPa) is strongly correlated with manufacturing problems.The effect of lubricant concentration on tabletability, tablet ejection and detachment can be evaluated using the Gamlen D series. Lubricant effectiveness rank order varies between materials; some...

25. February 2017

Abstract Punch sticking is a frequently occurring problem that challenges successful tablet manufacturing. A mechanistic understanding of the punch sticking phenomenon facilitates the design of effective strategies to solve punch sticking problems of a drug. The first step in this effort is to identify process parameters and particle properties that can profoundly affect sticking performance. This work was aimed at elucidating the key material properties and compaction parameters that influence...

18. October 2016

Purpose The present study details characterisation of the electrostatic properties of a range of active pharmaceutical ingredients (APIs) and blends and investigates the role of electrostatics as a potential root cause of punch sticking during tabletting. Methods Microcrystalline cellulose (AVICEL® PH-102) and magnesium stearate were used to prepare blends of constant drug loading (10% w/w) with a range of APIs. The electrostatic properties of the APIs and blends were then determined using a...