- Home

- Blog

- News

- Basics

- Sources

- Agencies, Regulatory & Organisations

- CERSI Excipients Browser

- Excipient Report

- Excipient DMF List

- EXCiPACT Certified Companies

- Excipient Documentation

- Excipient EINECS Numbers

- Excipient E-Numbers

- FDA Inactive Ingredient List

- FDA GRAS Substances (SCOGS) Database

- IPEC Americas

- USP - U.S. Pharmacopeia

- Definitions

- Whitepapers / Publications

- Supplier

- Services

- Media

- Events

- 1st pharmaexcipients Poster Award

- Event Calendar

- Events featured by pharma-excipients

- 4th Annual Formulation & Drug Delivery Congress

- DDF Summit

- ExcipientFest Americas

- ExcipientFest Asia

- Global CompliancePanel

- International Conference and Exhibition on Pharmaceutics & Novel Drug Delivery Systems

- Formulation & Drug Delivery USA Congress

- Laboratory Medicine 2018

- Making Pharmaceuticals Europe

- Making Pharmaceuticals Exhibition

- Pharma Integrates

- PharmaExcipients China @CPhI China

- TTC Technology Training Center

- Jobs

- Online Sourcing

- Contact

01. October 2018

The occurrence of protein aggregation during bioprocessing steps such as purification, formulation and fill-finish, impacts yield and production costs, and must be controlled throughout themanufacturing process. Understanding aggregation mechanisms and developing mitigating strategies are imperative to ensure the clinical efficacy of the protein drug product and to reduce costs. Thiscommentary reflects on recent progress made in the field of monoclonal antibody (mAb) aggregation with...

25. July 2018

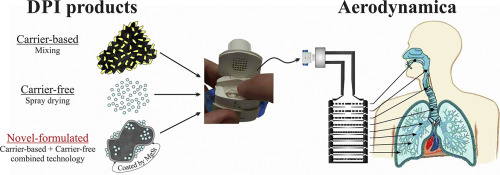

Dry Powder Inhaler (DPI) could offer a propellant-free, easy-to-use powder form ensuring better stability than liquid dosae forms. Therefore the development of traditional carrier-based and carrier-free new generation systems is a determinative factor in the field of DPI formulation. The purpose of our research work was to combine these two systems, utilizing their beneficial properties to produce a novel pulmonary drug delivery system containing ciprofloxacin hydrochloride (CIP). Co-spray...

16. October 2017

Excipients, once considered as far less important than the active pharmaceutical ingredient (API) in formulated medicines, today are receiving significantly more attention from both manufacturers and regulators. Many excipient technologies are no longer considered as simply inactive ingredients.

26. October 2016

Abstract The multiparticulate drug product concept covering micropellets, pellets, and mini-tablets is presented as a highly feasible approach to present convenient and patient friendly medication for the geriatric population. Improved swallowability and optimized administration regimen going along with defined drug dosage are achievable. Extemporaneous preparation of medicines from standard medication can be avoided going along with improved patient safety. With one multiparticulate pellet,...

21. September 2015

Hot Melt Extrusion (HME) is a well-known process within the plastic and food industries that has been utilized for the past several decades and is increasingly accepted by the pharmaceutical industry for continuous manufacturing. For tamper-resistant formulations of e.g.opioids, HME is the most efficient production technique. The focus of this study is thus to evaluate the manufacturability of the HME process for tamper-resistant formulations. More