- Home

- Blog

- News

- Basics

- Sources

- Agencies, Regulatory & Organisations

- CERSI Excipients Browser

- Excipient Report

- Excipient DMF List

- EXCiPACT Certified Companies

- Excipient Documentation

- Excipient EINECS Numbers

- Excipient E-Numbers

- FDA Inactive Ingredient List

- FDA GRAS Substances (SCOGS) Database

- IPEC Americas

- USP - U.S. Pharmacopeia

- Definitions

- Whitepapers / Publications

- Supplier

- Services

- Media

- Events

- 1st pharmaexcipients Poster Award

- Event Calendar

- Events featured by pharma-excipients

- 4th Annual Formulation & Drug Delivery Congress

- DDF Summit

- ExcipientFest Americas

- ExcipientFest Asia

- Global CompliancePanel

- International Conference and Exhibition on Pharmaceutics & Novel Drug Delivery Systems

- Formulation & Drug Delivery USA Congress

- Laboratory Medicine 2018

- Making Pharmaceuticals Europe

- Making Pharmaceuticals Exhibition

- Pharma Integrates

- PharmaExcipients China @CPhI China

- TTC Technology Training Center

- Jobs

- Online Sourcing

- Contact

26. September 2018

Wet granulation is a size-enlargement process applied in many industrial fields, such as pharmaceutical, nutraceutical, zootecnichal, to improve flowability and compressibility properties of powders. In this work analysis of the particle size distribution (PSD) of granules was performed to understand the phenomena involved during the granulation process and to optimize the operating conditions. Hydroxypropyl methylcellulose (HPMC) granules were produced spraying distilled water as liquid binder...

10. April 2018

"Glatt goes Compact and Modular" - Glatt Ingenieurtechnik has added compact continuous agglomeration equipment and new control systems to its "Modular Plant Engineering" Portfolio. At ACHEMA, the leading international trade fair for the process industries in June in Frankfurt am Main, market leading supplier of fluidized bed and spouted bed systems, Glatt, will showcase several new developments, including a compact system for continuous agglomeration and a modular control system that’s easy...

28. November 2017

Particle design via spherical agglomeration is a size enlargement technique used in various bulk and fine chemical industries, with recent interest extending into pharmaceuticals, in which an immiscible bridging liquid is added to agglomerate crystals prior to deliquoring. Spherical agglomeration has the potential to dramatically simplify downstream processing, and improves the handling of difficult, needle-shaped crystals. This review consolidates the understanding of the controlling process...

30. October 2017

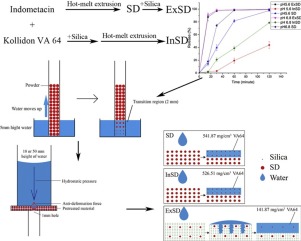

The purpose of this work was to investigate the effect on the dissolution behavior when silica was added in different ways. The solid dispersion was prepared by hot-melt extrusion (HME) using indomethacin (IND) as a model drug and Kollidon VA64 as a carrier.

04. July 2016

Abstract We aimed to elucidate the mechanism of the spheronization of pharmaceutical material crystals through extremely high shearing force using a mechanical powder processor, which produces spherical crystals without a solvent. The spheronization of theophylline, acetaminophen, clarithromycin, ascorbic acid and lactose was investigated, and the relationship between the spheronization mechanism and material characteristics was also examined. Theophylline and ascorbic acid crystals were...

07. June 2016

ABSTRACT Lipid excipients are applied for numerous purposes such as taste masking, controlled release, improvement of swallowability and moisture protection. Several melting techniques have evolved in the last decades. Common examples are melt coating, melt granulation and melt extrusion. The required equipment ranges from ordinary glass beakers for lab scale up to large machines such as fluid bed coaters, spray dryers or extruders. This allows for upscaling to pilot or production scale....

09. March 2016

In wet granulation processes, coatings or binders generally consist of mixtures of various raw materials that confer or enhance specific properties to the final product. Typically, a coating solution is composed of water, film forming polymer (such as hydroxypropyl-methylcellulose, HPMC) and filler (such as stearic acid, SA). One of the important issues in wet granulation processes is the stability of the aqueous coating (or binder) dispersion. An unstable dispersion results in the...

05. January 2016

In coating and agglomeration processes, the properties of the final product, such as solubility, size distribution, permeability and mechanical resistance, depend on the process parameters and the binder (or coating) solution properties. These properties include the type of solvent used, the binder composition and the affinity between its constituents. More

08. December 2015

Highlights • Geldart group C ibuprofen particles were silica dry coated to enable fluidization. • Aeration testing and flow function coefficient were indicative of fluidizability. • Dry coated ibuprofen powders could be fluidized and polymer film coated. • Polymer suspensions with stabilized colloidal silica led to reduced agglomeration. • Scalable coating conditions were determined for the micronized ibuprofen powders. More