- Home

- Blog

- News

- Basics

- Sources

- Agencies, Regulatory & Organisations

- CERSI Excipients Browser

- Excipient Report

- Excipient DMF List

- EXCiPACT Certified Companies

- Excipient Documentation

- Excipient EINECS Numbers

- Excipient E-Numbers

- FDA Inactive Ingredient List

- FDA GRAS Substances (SCOGS) Database

- IPEC Americas

- USP - U.S. Pharmacopeia

- Definitions

- Whitepapers / Publications

- Supplier

- Services

- Media

- Events

- 1st pharmaexcipients Poster Award

- Event Calendar

- Events featured by pharma-excipients

- 4th Annual Formulation & Drug Delivery Congress

- DDF Summit

- ExcipientFest Americas

- ExcipientFest Asia

- Global CompliancePanel

- International Conference and Exhibition on Pharmaceutics & Novel Drug Delivery Systems

- Formulation & Drug Delivery USA Congress

- Laboratory Medicine 2018

- Making Pharmaceuticals Europe

- Making Pharmaceuticals Exhibition

- Pharma Integrates

- PharmaExcipients China @CPhI China

- TTC Technology Training Center

- Jobs

- Online Sourcing

- Contact

01. October 2018

In this study, a set of 24 experiments was designed to understand the combined effect of different process parameters, i.e. material feed rate, liquid-to-solid (L/S) ratio, screw speed, and screw configuration on the residence time distribution, granule morphology, and particle size distribution in twin screw wet granulation of microcrystalline cellulose. It was shown that residence times were longer at higher L/S and lower screw speeds. However, the most dominant effect on mean residence time...

31. August 2018

Sugars and sweeteners are common ingredients in foods and also in pharmaceutical industries. They are soluble and sticky ingredients and their processing in granulators may be difficult since they can easily adhere to mixer walls or leadto uncontrolled granule growth. The purpose of this research was to evaluate the feasibility of the high shear wet granulation process and to find the optimal amount of binder by studying the granulation performances of four sugars: mannitol, sorbitol, xylitol...

20. July 2018

Soluplus® has been approved in generics in Taiwan and Argentina and now filed in Brazil. Would like to be kept updated on Soluplus® regulatory status or need further Information? Sign up here!

19. July 2018

Did you know that Soluplus® is already approved in generics in Taiwan and Argentina and now filed in Brazil? Check the submentioned Soluplus® one pager with updated regulatory status per country. Soluplus® Key Customer Benefits Outstanding solubilization properties, especially for poorly soluble APIs Enables bioavailability enhancement Ideal for hot melt extrusion and all standard granulation techniques Market proven solution for unique formulation challenges Would like to be kept updated on...

07. July 2018

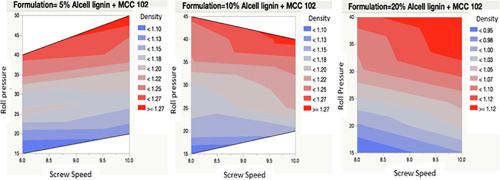

In this study, a process map was developed in an effort to improve the understanding of dry granulation of pharmaceutical excipients by roll compaction process, and to implement the quality-by-design (QbD) approach. Through development of the process map, a correlation was made between the critical process parameters (roll pressure, screw speed), and critical quality attributes (density of ribbons and granule size). This method reduces development time, quantity of materials required and cost....

07. June 2018

Wet granulation is mostly used process for manufacturing matrix tablets. Compared to the direct compression method, it allows for a better flow and compressibility properties of compression mixtures. Granulation, including process parameters and tableting, can influence critical quality attributes (CQAs) of hydrophilic matrix tablets. One of the most important CQAs is the drug release profile. We studied the influence of granulation process parameters (type of nozzle and water quantity used as...

02. June 2018

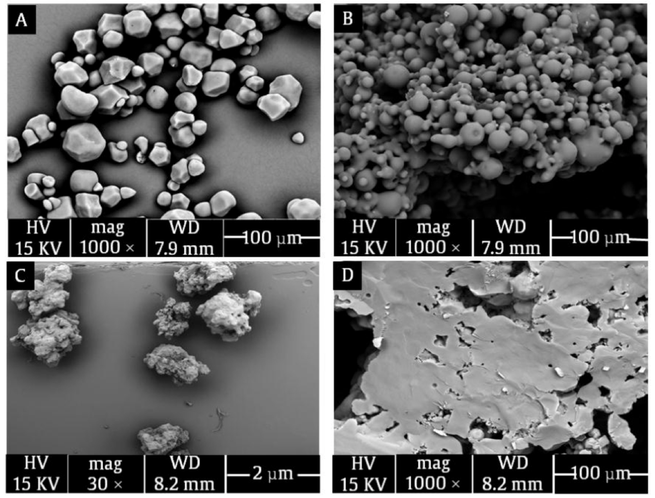

The objective of this article is to investigate the effects of fluidized bed granulation with dextrin on moisture sorption and diffusion of Zexie Decoction granules. Methods The particle characterization was studied by the particle size, scanning electron microscopy (SEM), differential scanning calorimetry (DSC), and Fourier transform infrared (FTIR). The moisture sorption isotherm, equilibrium moisture content (EMC), and moisture diffusion coefficients were determined by using the saturated...

19. April 2018

Excipients are materials added along with therapeutic agents; and incompatibility between excipients and therapeutic agents affect the final outcome of the product. Aspirin is an ester and is prone to hydrolysis. This study focus on the effect of magnesium stearate as an excipient on stability of aspirin in granules. For that an accelerated degradation study was done on aspirin-magnesium stearate containing granules. For that, aspirin containing granules were sequentially mixed with increasing...

04. April 2018

A full day of lectures on the Basics of

Granulation, Wurster Coating, Tablet

Compression, Tooling and Troubleshooting