- Home

- Blog

- News

- Basics

- Sources

- Agencies, Regulatory & Organisations

- CERSI Excipients Browser

- Excipient Report

- Excipient DMF List

- EXCiPACT Certified Companies

- Excipient Documentation

- Excipient EINECS Numbers

- Excipient E-Numbers

- FDA Inactive Ingredient List

- FDA GRAS Substances (SCOGS) Database

- IPEC Americas

- USP - U.S. Pharmacopeia

- Definitions

- Whitepapers / Publications

- Supplier

- Services

- Media

- Events

- 1st pharmaexcipients Poster Award

- Event Calendar

- Events featured by pharma-excipients

- 4th Annual Formulation & Drug Delivery Congress

- DDF Summit

- ExcipientFest Americas

- ExcipientFest Asia

- Global CompliancePanel

- International Conference and Exhibition on Pharmaceutics & Novel Drug Delivery Systems

- Formulation & Drug Delivery USA Congress

- Laboratory Medicine 2018

- Making Pharmaceuticals Europe

- Making Pharmaceuticals Exhibition

- Pharma Integrates

- PharmaExcipients China @CPhI China

- TTC Technology Training Center

- Jobs

- Online Sourcing

- Contact

01. October 2018

In this study, a set of 24 experiments was designed to understand the combined effect of different process parameters, i.e. material feed rate, liquid-to-solid (L/S) ratio, screw speed, and screw configuration on the residence time distribution, granule morphology, and particle size distribution in twin screw wet granulation of microcrystalline cellulose. It was shown that residence times were longer at higher L/S and lower screw speeds. However, the most dominant effect on mean residence time...

13. September 2018

Orodispersible films (ODFs) provide high application comfort due to rapid disintegration in the oral cavity. They increasingly found the approval of pharmaceutical research and development and were added to the European Pharmacopeia in 2012. The European Pharmacopeia explicitly demands disintegration testing for ODFs, but does not refer to a suitable method. The aim of this study was to collect and evaluate existing disintegration methods regarding their suitability to investigate different ODF...

02. September 2018

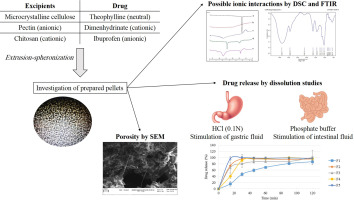

This study aimed to evaluate the potential of applying pectin and chitosan polysaccharides in pellet formulation. These biopolymers have advantages such as biocompatibility, low toxicity, low price and easy processing which make them interesting candidates for drug delivery purposes. Careful control of pellet porosity is essential to achieve an appropriate drug release profile. Replacing microcrystalline cellulose (MCC) with polysaccharides, especially pectin, leads to increased pellet...

01. September 2018

Flow properties of microcrystalline cellulose (MCC) excipients, Avicel PH 101 and Avicel PH 102 have been compared by using Brookfield PFT. Afterwards, the effect of hydrophobic Silica R972 as glidant has been tested on both the excipients. Hand blending is done by mixing MCCs with hydrophobic silica R972 vigorously by SAC as an underlined basis for 10 minutes and the flow properties tests are performed. During the flow function test “as received” Avicel PH 102 shows better flow function...

07. July 2018

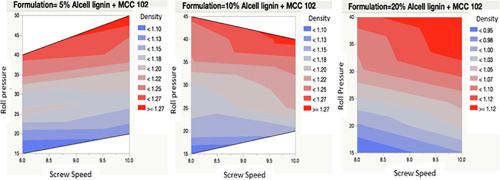

In this study, a process map was developed in an effort to improve the understanding of dry granulation of pharmaceutical excipients by roll compaction process, and to implement the quality-by-design (QbD) approach. Through development of the process map, a correlation was made between the critical process parameters (roll pressure, screw speed), and critical quality attributes (density of ribbons and granule size). This method reduces development time, quantity of materials required and cost....

01. March 2018

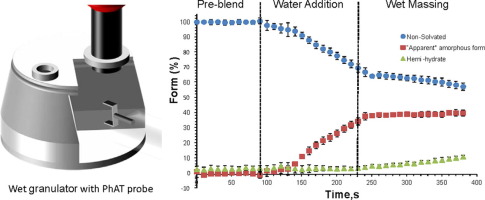

Form changes during drug product processing can be a risk to the final product quality in terms of chemical stability and bioavailability. In this study, online Raman spectroscopy was used to monitor the form changes in real time during high shear wet granulation of Compound A, a highly soluble drug present at a high drug load in an extended release formulation. The effect of water content, temperature, wet massing time and drying technique on the degree of drug transformation were examined.

02. May 2017

Highlights

• Binder properties were correlated to granule and tablet properties.

• Groups of binders behave divergent regarding granule and tablet properties.

• Povidone based polymers seem to have another binding behaviour.

• Disintegration of tablets was explained by particle size and viscosity effects.

• Changes in particle size caused larger effects for small-sized binders on tablets.

31. January 2017

Abstract The adsorption behavior of some metal ions (Pb, Mn, Mg, Zn and Ca) was studied on silicon dioxide nanoparticles, SiO2 NP, alone and its mixture with microcrystalline cellulose, MCC, powder (1:1) as drug carriers in pharmaceutical preparations. The effect of different conditions as temperature and pH on adsorption was investigated. It was found that upon increasing the temperature, the ability of the adsorbent material increases. The pH of the metal solution has the same effect as...

08. January 2017

ABSTRACT: In the present study, novel co-processed superdisintegrants were developed by spray drying method using microcrystalline cellulose and mannitol in different ratios (1:1, 1:2 and 1:3) for use in the fast dissolving tablet formulations. The developed excipients were evaluated for angle of repose, Carr’s index and Hausner’s ratio in comparison with physical mixture of superdisintegrants. The angle of repose of the developed excipients was found to be < 30o, Carr’s index in the...

06. January 2017

Abstract Microcrystalline cellulose (MCC) HiCelTM is native from cellulose, which is manufactured from wood pulp. Microcrystalline cellulose is made by hydrolysis reaction at temperature and pressure in presence of catalyst, which acts as reaction process increment. It is neutralized after completion of hydrolysis and intended to be used as to make microcrystalline cellulose powder. HiCelTM MCC is white crystalline, free flowing powder and medium in particles size. MCC is free flowing with...