- Home

- Blog

- News

- Basics

- Sources

- Agencies, Regulatory & Organisations

- CERSI Excipients Browser

- Excipient Report

- Excipient DMF List

- EXCiPACT Certified Companies

- Excipient Documentation

- Excipient EINECS Numbers

- Excipient E-Numbers

- FDA Inactive Ingredient List

- FDA GRAS Substances (SCOGS) Database

- IPEC Americas

- USP - U.S. Pharmacopeia

- Definitions

- Whitepapers / Publications

- Supplier

- Services

- Media

- Events

- 1st pharmaexcipients Poster Award

- Event Calendar

- Events featured by pharma-excipients

- 4th Annual Formulation & Drug Delivery Congress

- DDF Summit

- ExcipientFest Americas

- ExcipientFest Asia

- Global CompliancePanel

- International Conference and Exhibition on Pharmaceutics & Novel Drug Delivery Systems

- Formulation & Drug Delivery USA Congress

- Laboratory Medicine 2018

- Making Pharmaceuticals Europe

- Making Pharmaceuticals Exhibition

- Pharma Integrates

- PharmaExcipients China @CPhI China

- TTC Technology Training Center

- Jobs

- Online Sourcing

- Contact

18. March 2018

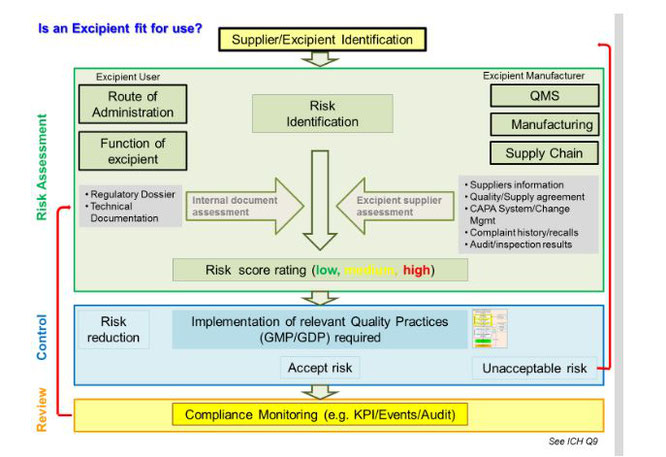

This article describes a new, combined, quantitative method for assessing excipient risks that has been developed by the authors as one possible risk evaluation method. According to the modern requirements of the European Union’s Good Manufacturing Practice for Medicinal Products, a manufacturing authorization holder should guarantee the suitability of excipients included in the finished medicine. For this purpose, a formalized, documented assessment of risks associated with safety, quality,...

22. February 2018

A public workshop entitled “Challenges and strategies to facilitate formulation development of pediatric drug products” focused on current status and gaps as well as recommendations for risk-based strategies to support the development of pediatric age-appropriate drug products. Representatives from industry, academia, and regulatory agencies discussed the issues within plenary, panel, and case-study breakout sessions. By enabling practical and meaningful discussion between scientists...

12. February 2018

Excipients are crucial ingredients in final drug formulations with potential impacts on product quality, stability, tolerance, release profiles, local distribution and availability, and thus overall efficacy and safety. Recent regulations have increased the requirements for drug manufacturers and excipient suppliers with respect to ensuring the quality and safety of excipients.

15. September 2017

Excipients are critical for a drug to be effective. However, they can also cause great harm if their quality if poor. By creating standards for excipients, we play a key role in ensuring the purity of the whole drug. This column discusses the updates to and harmonization of excipient USP-NF standards and the importance of collaborative efforts with FDA and USP stakeholders. http://bit.ly/2wcT7Em

04. September 2017

Abstract Excipients are an integral part of practically all medicines. Historically, excipients have been regarded as pharmacologically and chemically indifferent within the formulation. However, nowadays excipients along with active pharmaceutical ingredients are the subject of strict monitoring and quality control in pharmaceutical manufacture. According to the current rules of European Union’s Good Manufacturing Practice of Medicinal Products excipients should be subjected to a thorough...

21. April 2017

Excipients serve a critical role in the production of final dosage forms for drug products and biologics. They facilitate the manufacturing process (e.g., anticaking agents) and protect, support, and enhance stability. They may also improve bioavailability. In addition, excipients help maintain the safety, or function, of the product during storage and use. No longer characterized as inert accompaniments to an active pharmaceutical ingredient (API), excipients are the target of an intensified...

21. March 2017

by: Frithjof Holtz, Merck KGaA, Darmstadt, Germany | Dec 06, 2016 Excipients serve a critical role in the production of final dosage forms for drug products and biologics. They facilitate the manufacturing process (e.g., anticaking agents) and protect, support, and enhance stability. They may also improve bioavailability. In addition, excipients help maintain the safety, or function, of the product during storage and use. No longer characterized as inert accompaniments to an active...

19. December 2016

Vendor selection and materials testing are complex enough, but in today’s volatile environment, risk mapping and monitoring are also crucial. Choosing excipients and suppliers for pharmaceutical formulations requires a clear understanding of product requirements; material properties; product, process, and material variability; and vendor practices. The goal is a safe, robust formulation that will meet bioequivalence and stability requirements, but also enable validatable manufacturing,...

20. July 2016

ABSTRACT The goal of this study was to utilize risk assessment techniques and statistical design of experiments (DoE) to gain process understanding and to identify critical process parameters for the manufacture of controlled release multiparticulate beads using a novel disk-jet fluid bed technology. The material attributes and process parameters were systematically assessed using the Ishikawa fish bone diagram and failure mode and effect analysis (FMEA) risk assessment methods. The high risk...

10. July 2016

Abstract The current work outlines the application of an up-to-date and regulatory-based pharmaceutical quality management method, applied as a new development concept in the process of formulating dry powder inhalation systems (DPIs). According to the Quality by Design (QbD) methodology and Risk Assessment (RA) thinking, a mannitol based co-spray dried formula was produced as a model dosage form with meloxicam as the model active agent. The concept and the elements of the QbD approach...