- Home

- Blog

- News

- Basics

- Sources

- Agencies, Regulatory & Organisations

- CERSI Excipients Browser

- Excipient Report

- Excipient DMF List

- EXCiPACT Certified Companies

- Excipient Documentation

- Excipient EINECS Numbers

- Excipient E-Numbers

- FDA Inactive Ingredient List

- FDA GRAS Substances (SCOGS) Database

- IPEC Americas

- USP - U.S. Pharmacopeia

- Definitions

- Whitepapers / Publications

- Supplier

- Services

- Media

- Events

- 1st pharmaexcipients Poster Award

- Event Calendar

- Events featured by pharma-excipients

- 4th Annual Formulation & Drug Delivery Congress

- DDF Summit

- ExcipientFest Americas

- ExcipientFest Asia

- Global CompliancePanel

- International Conference and Exhibition on Pharmaceutics & Novel Drug Delivery Systems

- Formulation & Drug Delivery USA Congress

- Laboratory Medicine 2018

- Making Pharmaceuticals Europe

- Making Pharmaceuticals Exhibition

- Pharma Integrates

- PharmaExcipients China @CPhI China

- TTC Technology Training Center

- Jobs

- Online Sourcing

- Contact

31. August 2018

Sugars and sweeteners are common ingredients in foods and also in pharmaceutical industries. They are soluble and sticky ingredients and their processing in granulators may be difficult since they can easily adhere to mixer walls or leadto uncontrolled granule growth. The purpose of this research was to evaluate the feasibility of the high shear wet granulation process and to find the optimal amount of binder by studying the granulation performances of four sugars: mannitol, sorbitol, xylitol...

07. June 2018

Wet granulation is mostly used process for manufacturing matrix tablets. Compared to the direct compression method, it allows for a better flow and compressibility properties of compression mixtures. Granulation, including process parameters and tableting, can influence critical quality attributes (CQAs) of hydrophilic matrix tablets. One of the most important CQAs is the drug release profile. We studied the influence of granulation process parameters (type of nozzle and water quantity used as...

01. March 2018

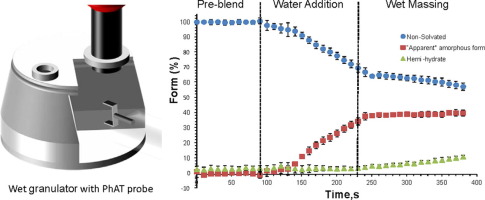

Form changes during drug product processing can be a risk to the final product quality in terms of chemical stability and bioavailability. In this study, online Raman spectroscopy was used to monitor the form changes in real time during high shear wet granulation of Compound A, a highly soluble drug present at a high drug load in an extended release formulation. The effect of water content, temperature, wet massing time and drying technique on the degree of drug transformation were examined.

06. November 2017

Many efforts have been made in the past to understand the function of lactose fines which are given as a ternary component to carrier-based dry powder inhaler formulations. It is undisputed that fines can significantly improve the performance of such formulations, but choosing the right amount of fines is a crucial point, because too high concentrations can have negative effects on the dispersion performance

20. April 2017

Abstract The purpose of this study is to demonstrate that the flow function (FFc) of pharmaceutical powders, as measured by rotational shear cell, is predominantly governed by cohesion, but not friction coefficients. Driven by an earlier report showing an inverse correlation between FFc and the cohesion divided by the corresponding pre-consolidation stress [Wang et al. 2016. Powder Tech. 294:105-112], we performed analysis on a large dataset containing 1130 measurements from a ring shear...

07. April 2017

Abstract High shear mixers are classically used for wet granulation because they provide granules with a high density and a high strength in a short granulation time. In this study, the high shear wet granulation process was employed using chlorpheniramine maleate as a model drug, since it represents an example of low dose drug employing 32 randomized full factorial design and optimized in terms of different properties using Response Surface Methodology (RSM) approach. The effect of binder...

26. March 2017

Abstract The aim of this study was to prepare controlled-release (CR) granules with suitable particle strength, flowability, particle size distribution (PSD) and density characteristics for blending with other excipients. We also wanted these CR granules to contain large quantities of active pharmaceutical ingredient (API). A high shear mixer was used to mix an API with various polymers at various feed ratios, and the resulting granulated materials were sprayed with solvent. The wet granules...

15. August 2016

Abstract The methods used for flow characterization of a powder mass include the angle of repose (AOR), Carr index (CI), and powder flow tester (PFT). The use of nanosilica as a flow modifier (glidant) is very common in industry. This study aims to compare the glidant effect of hydrophobic and hydrophilic silica on a poorly flowable active pharmaceutical ingredient (ibuprofen) by different flow characterization techniques. Different percentages (0.5, 1.0, and 2.0 wt%) of both types of mixed...

15. June 2016

Context: The negative impact of magnesium stearate on the hardness of tablets is a well-known phenomenon, but the influence of paddle movement in the forced feeder on the lubricant effect during tablet compression is often neglected. Objective: The purpose of this research was to investigate the influence of paddle speed in the forced feeder on tablet tensile strength. Materials and methods: Mixtures of microcrystalline cellulose and magnesium stearate (0.5%) were blended using different...

04. June 2016

A full factorial design of experiments was used to study the effect of blend shear strain on the compaction process, relative density and strength of pharmaceutical tablets. The powder blends were subjected to different shear strain levels (integral of shear rate with respect to time) using an ad hoc Couette shear cell. Tablets were compressed at different compaction forces using an instrumented compactor simulator, and compaction curves showing the force-displacement profiles during compaction...