- Home

- Blog

- News

- Basics

- Sources

- Agencies, Regulatory & Organisations

- CERSI Excipients Browser

- Excipient Report

- Excipient DMF List

- EXCiPACT Certified Companies

- Excipient Documentation

- Excipient EINECS Numbers

- Excipient E-Numbers

- FDA Inactive Ingredient List

- FDA GRAS Substances (SCOGS) Database

- IPEC Americas

- USP - U.S. Pharmacopeia

- Definitions

- Whitepapers / Publications

- Supplier

- Services

- Media

- Events

- 1st pharmaexcipients Poster Award

- Event Calendar

- Events featured by pharma-excipients

- 4th Annual Formulation & Drug Delivery Congress

- DDF Summit

- ExcipientFest Americas

- ExcipientFest Asia

- Global CompliancePanel

- International Conference and Exhibition on Pharmaceutics & Novel Drug Delivery Systems

- Formulation & Drug Delivery USA Congress

- Laboratory Medicine 2018

- Making Pharmaceuticals Europe

- Making Pharmaceuticals Exhibition

- Pharma Integrates

- PharmaExcipients China @CPhI China

- TTC Technology Training Center

- Jobs

- Online Sourcing

- Contact

19. March 2018

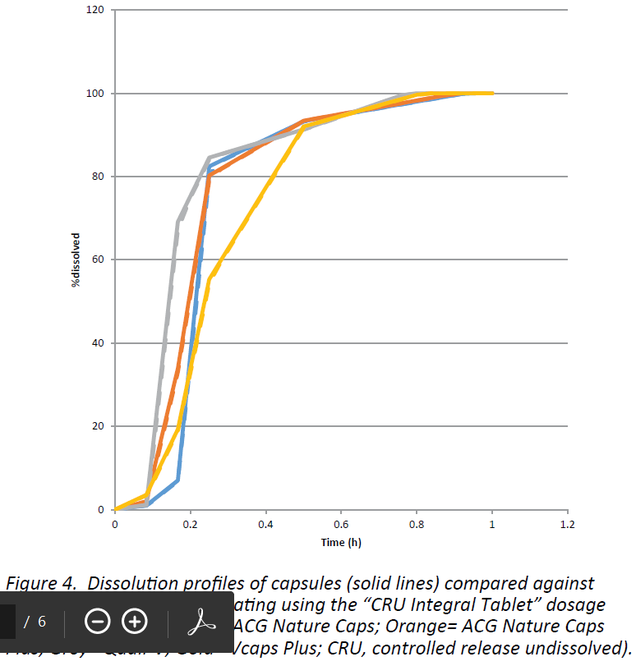

The effect of using different HPMC hard capsule shells on the in vitro dissolution profile of acetaminophen powder wasinvestigated. Use of HPMC capsule shells from different manufacturers resulted in different in vitro dissolution profiles.These differences were unrelated to the presence or absence of a gelling agent (carrageenan) in the capsule shells whenpotassium was absent from the dissolution media.

09. December 2017

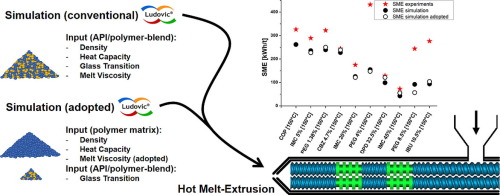

Simulation of HME processes is a valuable tool for increased process understanding and ease of scale-up. However, the experimental determination of all required input parameters is tedious, namely the melt rheology of the amorphous solid dispersion (ASD) in question.

03. April 2017

Abstract Capping or lamination is an unsolved common problem in tablet manufacturing. Knowledge gaps remain despite an enormous amount of effort made in the past to better understand the tablet capping/lamination phenomenon. Using acetaminophen – containing formulations, we examined the potential use of a compaction simulator as a material-sparing tool to predict capping occurrence under commercial tableting conditions. Systematical analyses of the in-die compaction data led to insight on the...

02. June 2016

Phospholipid-based formulations provide a key technology to formulate poorly water-soluble drugs. A recent interest has been in using phospholipids with a high content of monoacyl phosphatidylcholine (monoacyl PC) due to its ability to form mixed micelles of mono- and di-acylphospholipids upon aqueous dispersion. The present work focused on binary drug- monoacyl PC systems (at about equimolar ratio) with respect to screening of solid dispersion feasibility. It was tested whether or not a...

24. March 2016

The increasing demand for personalized medicine necessitates the production of easily customizable dosage forms. As the number of possible dosage forms may scale towards infinity, their uniqueness require a versatile production platform and numerical simulation in order to be manufactured efficiently. A mathematical description of these systems is the only feasible approach to manage such diverse properties of different products. However, experimental verification is still essential for...

09. March 2016

In wet granulation processes, coatings or binders generally consist of mixtures of various raw materials that confer or enhance specific properties to the final product. Typically, a coating solution is composed of water, film forming polymer (such as hydroxypropyl-methylcellulose, HPMC) and filler (such as stearic acid, SA). One of the important issues in wet granulation processes is the stability of the aqueous coating (or binder) dispersion. An unstable dispersion results in the...

05. January 2016

In coating and agglomeration processes, the properties of the final product, such as solubility, size distribution, permeability and mechanical resistance, depend on the process parameters and the binder (or coating) solution properties. These properties include the type of solvent used, the binder composition and the affinity between its constituents. More

07. May 2015

The Compaction Simulation Forum (CSF) was formed in order to better leverage industry, academic experience and learning with compaction simulation http://www.compactionsimulation.com/compaction-education/2015-forum/

10. February 2015

The Compaction Simulation Forum (CSF) was formed in order to better leverage industry, academic experience and learning with compaction simulation... http://www.compactionsimulation.com/compaction-education/2015-forum/2015-forum-agenda/