- Home

- Blog

- News

- Basics

- Sources

- Agencies, Regulatory & Organisations

- CERSI Excipients Browser

- Excipient Report

- Excipient DMF List

- EXCiPACT Certified Companies

- Excipient Documentation

- Excipient EINECS Numbers

- Excipient E-Numbers

- FDA Inactive Ingredient List

- FDA GRAS Substances (SCOGS) Database

- IPEC Americas

- USP - U.S. Pharmacopeia

- Definitions

- Whitepapers / Publications

- Supplier

- Services

- Media

- Events

- 1st pharmaexcipients Poster Award

- Event Calendar

- Events featured by pharma-excipients

- 4th Annual Formulation & Drug Delivery Congress

- DDF Summit

- ExcipientFest Americas

- ExcipientFest Asia

- Global CompliancePanel

- International Conference and Exhibition on Pharmaceutics & Novel Drug Delivery Systems

- Formulation & Drug Delivery USA Congress

- Laboratory Medicine 2018

- Making Pharmaceuticals Europe

- Making Pharmaceuticals Exhibition

- Pharma Integrates

- PharmaExcipients China @CPhI China

- TTC Technology Training Center

- Jobs

- Online Sourcing

- Contact

01. October 2018

In this study, a set of 24 experiments was designed to understand the combined effect of different process parameters, i.e. material feed rate, liquid-to-solid (L/S) ratio, screw speed, and screw configuration on the residence time distribution, granule morphology, and particle size distribution in twin screw wet granulation of microcrystalline cellulose. It was shown that residence times were longer at higher L/S and lower screw speeds. However, the most dominant effect on mean residence time...

07. June 2018

Wet granulation is mostly used process for manufacturing matrix tablets. Compared to the direct compression method, it allows for a better flow and compressibility properties of compression mixtures. Granulation, including process parameters and tableting, can influence critical quality attributes (CQAs) of hydrophilic matrix tablets. One of the most important CQAs is the drug release profile. We studied the influence of granulation process parameters (type of nozzle and water quantity used as...

01. March 2018

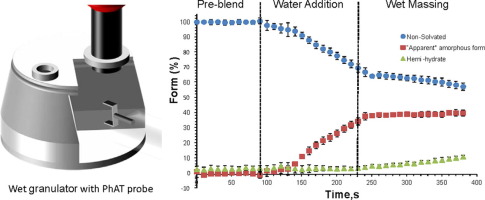

Form changes during drug product processing can be a risk to the final product quality in terms of chemical stability and bioavailability. In this study, online Raman spectroscopy was used to monitor the form changes in real time during high shear wet granulation of Compound A, a highly soluble drug present at a high drug load in an extended release formulation. The effect of water content, temperature, wet massing time and drying technique on the degree of drug transformation were examined.

21. April 2017

Abstract The potential of fine excipient materials to improve the performance of carrier-based dry powder inhalation mixtures is well acknowledged. The mechanisms underlying this potential are, however, open to question till date. Elaborate understanding of these mechanisms is a requisite for rational rather than empirical development of ternary dry powder inhalation mixtures. While effects of fine excipient materials on drug adhesion to and detachment from surfaces of carrier particle have...

07. April 2017

Abstract High shear mixers are classically used for wet granulation because they provide granules with a high density and a high strength in a short granulation time. In this study, the high shear wet granulation process was employed using chlorpheniramine maleate as a model drug, since it represents an example of low dose drug employing 32 randomized full factorial design and optimized in terms of different properties using Response Surface Methodology (RSM) approach. The effect of binder...

06. March 2017

Abstract The present study investigates the effects of formulation and process parameters on the production of aprepitant nanosuspensions applying wet media milling and subsequent solidification. Six stabilizers were used: two brands of hydroxylpropylmethyl cellulose (HPMC E-15LV and Pharmacoat 603), hydroxypropyl cellulose (HPC-SSL), polyvinylpyrollidone (PVP), D-α-Tocopherol polyethylene glycol 1000 succinate (TPGS 1000), Poloxamer P188 and sodium dodecyl sulfate (SDS), while two diluents...

20. February 2017

Abstract The overall objective of this work is to understand how excipient characteristics influence the process and product performance for a continuous twin-screw wet granulation process. The knowledge gained through this study is intended to be used for a Quality by Design (QbD)-based formulation design approach and formulation optimization. A total of 9 preferred fillers and 9 preferred binders were selected for this study. The selected fillers and binders were extensively characterized...

09. February 2017

Abstract Computational modelling of twin-screw granulation was conducted by using an artificial neural network (ANN) approach. Various ANN configurations were considered with changing hidden layers, nodes and activation functions to determine the optimum model for the prediction of the process. The neural networks were trained using experimental data obtained for granulation of pure microcrystalline cellulose using a 12 mm twin-screw extruder. The experimental data were obtained for various...

20. December 2016

Abstract Salt disproportionation (a conversion from the ionized to the neutral state) in solid formulations is a potential concern during manufacturing or storage of products containing a salt of the active pharmaceutical ingredient (API) due to the negative ramifications on product performance. However, it is challenging to find an effective approach to prevent or mitigate this undesirable reaction in formulations. Hence, the overall objective of this study is to explore novel formulation...

13. December 2016

Abstract Mixer torque rheometry (MTR) was evaluated as a pre-production (pre-formulation and optimization) tool for predicting ideal liquid-to-solid ratios (L/S) for extrusion-spheronisation of a wide range of APIs using 10 g formulations. APIs of low, medium and high solubility were formulated at low and high loadings (15 and 40% w/w, respectively) with PVP as binder (5%) and MCC as the major excipient. L/S corresponding to the maximum torque produced during wet massing in the MTR, L/S(maxT),...