Reproducibility of die fill during tablet production is critical to ensure consistent tablet drug content and mechanical attributes. In the production of

mini-tablets, tablets smaller than 6 mm, achievement of uniform die fill is much more challenging. Powder flow is often associated with die fill accuracy but this relationship has not

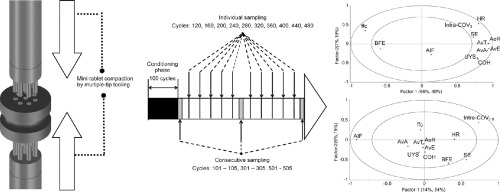

been well characterised especially for mini-tablets. In this study, flow properties of different types of granules were characterised. Mini-tablets of 1.8 and 3 mm diameters were prepared from

the granules using a rotary press with multiple-tip compression tooling. A methodology was established to evaluate mini-tablet die fill variation within and across compaction cycles using data from

compression roller displacement and mini-tablet weight. Both sizes of mini-tablets showed similar extents of inter-cycle weight variation that could be associated with granules’ inter-particulate

friction. However, smaller mini-tablets had higher intra-cycle weight variation due to their narrower die orifices. Multivariate and univariate analyses suggested that gravity fill influenced

intra-cycle weight variation of 3 mm mini-tablets while suction fill was associated with that of 1.8 mm mini-tablets. Possible differences in die fill mechanisms between the mini-tablet

sizes were identified and this provided a better insight into die fill variations during the production of mini-tablets.

- Home

- Blog

- News

- Basics

- Sources

- Agencies, Regulatory & Organisations

- CERSI Excipients Browser

- Excipient Report

- Excipient DMF List

- EXCiPACT Certified Companies

- Excipient Documentation

- Excipient EINECS Numbers

- Excipient E-Numbers

- FDA Inactive Ingredient List

- FDA GRAS Substances (SCOGS) Database

- IPEC Americas

- USP - U.S. Pharmacopeia

- Definitions

- Whitepapers / Publications

- Supplier

- Services

- Media

- Events

- 1st pharmaexcipients Poster Award

- Event Calendar

- Events featured by pharma-excipients

- 4th Annual Formulation & Drug Delivery Congress

- DDF Summit

- ExcipientFest Americas

- ExcipientFest Asia

- Global CompliancePanel

- International Conference and Exhibition on Pharmaceutics & Novel Drug Delivery Systems

- Formulation & Drug Delivery USA Congress

- Laboratory Medicine 2018

- Making Pharmaceuticals Europe

- Making Pharmaceuticals Exhibition

- Pharma Integrates

- PharmaExcipients China @CPhI China

- TTC Technology Training Center

- Jobs

- Online Sourcing

- Contact