Abstract

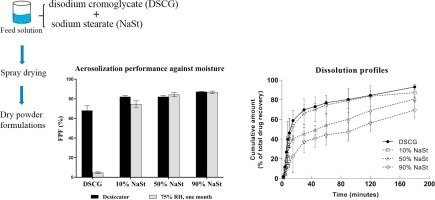

Amorphous powders are thermodynamically unstable, significantly impacting the processing, storage and performance of a product. Therefore, stabilization of the amorphous contents is in demand. In this study, disodium cromoglycate (DSCG) powder was chosen as a model drug because it is amorphous and highly hygroscopic after spray drying. Sodium stearate (NaSt) was co-spray dried with DSCG at various concentrations (10, 50 and 90% w/w) to investigate its effect against moisture-induced deterioration on the in vitro aerosolization performance of DSCG. Particle size distribution and morphology were measured by laser diffraction and scanning electron microscopy (SEM). Physicochemical properties of the powders were analysed by X-ray powder diffraction (XRPD) and dynamic vapour sorption (DVS). Particle surface chemistry was analysed by the time-of-flight secondary ion mass spectrometry (ToF-SIMS). In vitro dissolution behaviours of the spray-dried (SD) powders were tested by the Franz cell apparatus. In vitro aerosolization performance of SD formulations stored at different relative humidity (RH) was evaluated by a multi-stage liquid impinger (MSLI), using an Osmohaler® at 100 L/min. Results showed that adding NaSt in the formulation not only increased the aerosolization performance of DSCG significantly, but also effectively reduced the deleterious impact of moisture. No significant difference was found in the fine particle fraction (FPF) of formulations containing NaSt before and after storage at both 60% and 75% RH for one week. However, after one month storage at 75% RH, SD formulation containing 10% NaSt showed a reduction in FPF, while formulations containing 50% or 90% NaSt showed no change. The underlying mechanism was that NaSt increased the crystallinity of the powders and its presence on the particle surface reduced particle aggregations and cohesiveness. However, NaSt at high concentration could reduce dissolution rate, which needs to be taken into consideration.

Conclusions

The addition of NaSt in inhalable powder formulations not only improved the in vitro aerosol performance, but also decreased moisture- induced deterioration in aerosolization. The proposed mechanism for this enhancement is the crystallinity and coverage of NaSt on the par- ticle surface. This in turn is dependent on the concentration of NaSt present in the formulation. This investigation broadens the current understanding on sodium stearate as a moisture protective excipient on hygroscopic powders for inhalation drug delivery.