- Home

- Blog

- News

- Basics

- Sources

- Agencies, Regulatory & Organisations

- CERSI Excipients Browser

- Excipient Report

- Excipient DMF List

- EXCiPACT Certified Companies

- Excipient Documentation

- Excipient EINECS Numbers

- Excipient E-Numbers

- FDA Inactive Ingredient List

- FDA GRAS Substances (SCOGS) Database

- IPEC Americas

- USP - U.S. Pharmacopeia

- Definitions

- Whitepapers / Publications

- Supplier

- Services

- Media

- Events

- 1st pharmaexcipients Poster Award

- Event Calendar

- Events featured by pharma-excipients

- 4th Annual Formulation & Drug Delivery Congress

- DDF Summit

- ExcipientFest Americas

- ExcipientFest Asia

- Global CompliancePanel

- International Conference and Exhibition on Pharmaceutics & Novel Drug Delivery Systems

- Formulation & Drug Delivery USA Congress

- Laboratory Medicine 2018

- Making Pharmaceuticals Europe

- Making Pharmaceuticals Exhibition

- Pharma Integrates

- PharmaExcipients China @CPhI China

- TTC Technology Training Center

- Jobs

- Online Sourcing

- Contact

30. July 2018

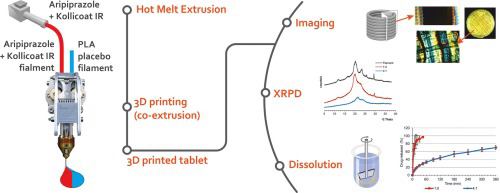

Three-dimensional printing is one of the fastest developing technology withinpharmaceutical field. With many advantages this method can be found as a new dosageform manufacturing technique, however low printing efficiency stays as one of the major limitations. Therefore, the preparation of filaments as a feedstock and printing of the final dosageforms in pharmacies may by the direction of development for this method. Thus, simple dosage and dissolution profile modification seems to be...

07. November 2017

Over the last few decades, hot melt extrusion (HME) has emerged as a successful technology for a broad spectrum of applications in the pharmaceutical industry. As indicated by multiple publications and patents, HME is mainly used for the enhancement of solubility and bioavailability of poorly soluble drugs. This review is focused on the recent reports on the solubility enhancement via HME and provides an update for the manufacturing/scaling up aspects of melt extrusion. In addition, drug...

06. November 2017

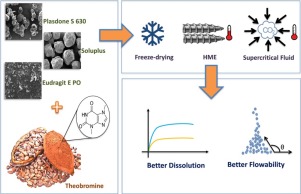

The aim of this study was to improve the pharmaceutical properties of theobromine (TB), particularly its flowability and dissolution rate, by preparing solid dispersions using different technologies (hot melt extrusion—HME, freeze-drying—FD, and supercritical fluid—SF) as well as testing different hydrophilic polymeric matrixes (Eudragit™ E, Plasdone™ S and Soluplus™)

11. April 2017

Abstract The purpose of this study was to explore the feasibility of combining fused deposition modeling (FDM) 3D printing technology with hot melt extrusion (HME) to fabricate a novel controlled-release drug delivery device. Glipizide used in the treatment of diabetes was selected as model drug, and was successfully loaded into commercial polyvinyl alcohol(PVA) filaments by HME method. The drug-loaded filaments were printed through a dual-nozzle 3D printer, and finally formed a double-chamber...

22. February 2017

Hot Melt Extrusion (HME) technology is a widely used for manufacturing process in the plastic and pharmaceutical industries and is an efficient and simple for the production of a solid dispersion. This technique is an environmental friendly, continuous process that does not use solvents. It is time and cost efficient and can be easily scaled up. In addition, HME may be used in conjunction with other technologies to effectively increase the solubility and dissolution rate of poorly water-soluble...

01. October 2016

Abstract The aim of this study was to evaluate hot-melt extrusion (HME) as a continuous process to form cyclodextrin (CD) inclusion complexes in order to increase the solubility and dissolution rate of itraconazole (ITZ), a class II model drug molecule of the Biopharmaceutics Classification System. Different CD derivatives were tested in a 1:1 (CD:ITZ) molar ratio to obtain CD ternary inclusion complexes in the presence of a polymer, namely Soluplus® (SOL). The CD used in this series of...

26. September 2016

Abstract Poly(ethylene oxide) (PEO)-based hot melt extrudates offer an interesting potential as oral controlled drug delivery systems and can provide additional advantages, such as reducing the risk of drug abuse. Different polymer molecular weight PEOs are commercially available and can be used to prepare drug-loaded hot melt extrudates. Importantly, the macromolecular chain length impacts crucial system features, including the swelling and erosion kinetics of the systems, which determine the...

24. May 2016

Fused deposition modeling (FDM) is a 3D printing technique based on the deposition of successive layers of thermoplastic materials following their softening/melting. Such a technique holds huge potential for the manufacturing of pharmaceutical products and is currently under extensive investigation. Challenges in this field are mainly related to the paucity of adequate filaments composed of pharmaceutical grade materials, which are needed for feeding the FDM equipment. Accordingly, a number of...

22. April 2016

The main route of administration for drug products is the oral route, yet biologics are initially developed as injectables due to their limited stability through the gastrointestinal tract and solubility issues. In order to avoid injections, a myriad of investigations on alternative administration routes that can bypass enzymatic degradation and the first-pass effect are found in the literature. As an alternative site for biologics absorption, the buccal route presents with a number of...

11. April 2016

Amorphous solid dispersion formulations have been widely used to enhance bioavailability of poorly soluble drugs. In these formulations, polymer is included to physically stabilize the amorphous drug by dispersing it in the polymeric carrier and thus forming a solid solution. The polymer can also maintain supersaturation and promote speciation during dissolution, thus enabling better absorption as compared to crystalline drug substance. In this paper, we report the use of hot melt extrusion...