- Home

- Blog

- News

- Basics

- Sources

- Agencies, Regulatory & Organisations

- CERSI Excipients Browser

- Excipient Report

- Excipient DMF List

- EXCiPACT Certified Companies

- Excipient Documentation

- Excipient EINECS Numbers

- Excipient E-Numbers

- FDA Inactive Ingredient List

- FDA GRAS Substances (SCOGS) Database

- IPEC Americas

- USP - U.S. Pharmacopeia

- Definitions

- Whitepapers / Publications

- Supplier

- Services

- Media

- Events

- 1st pharmaexcipients Poster Award

- Event Calendar

- Events featured by pharma-excipients

- 4th Annual Formulation & Drug Delivery Congress

- DDF Summit

- ExcipientFest Americas

- ExcipientFest Asia

- Global CompliancePanel

- International Conference and Exhibition on Pharmaceutics & Novel Drug Delivery Systems

- Formulation & Drug Delivery USA Congress

- Laboratory Medicine 2018

- Making Pharmaceuticals Europe

- Making Pharmaceuticals Exhibition

- Pharma Integrates

- PharmaExcipients China @CPhI China

- TTC Technology Training Center

- Jobs

- Online Sourcing

- Contact

29. September 2018

Appropriate lubrication is important in tablet manufacturing as it lowers punch sticking propensity and protects tooling by reducing friction between die wall and tablet during tablet manufacturing. Most commercial lubricants negatively impact tabletability and dissolution. A delicate balance is usually attained by trial and error to identify the optimal level of lubricant in a tablet formulation. In this work, we have evaluated the effectiveness of sodium lauryl sulfate (SLS), a surfactant, as...

17. July 2018

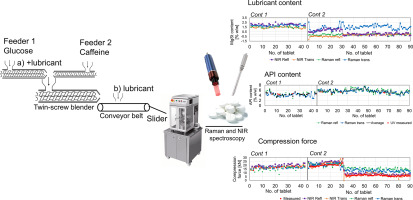

By the advent of continuous pharmaceutical manufacturing, fast and accurate characterization of product quality has become of a major interest. Although it also promotes the real-time release testing approach, so far mainly content uniformity studies were performed by near-infrared (NIR) spectroscopy. This paper proposes the simultaneous application of NIR and Raman spectroscopy to nondestructively analyze the critical quality attributes of continuously produced tablets in a real-time release...

26. February 2018

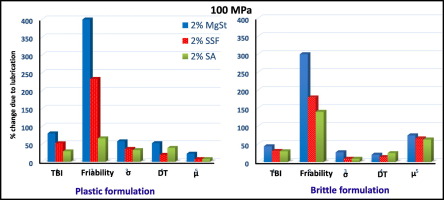

As an essential formulation component for large-scale tablet manufacturing, the lubricant preserves tooling by reducing die-wall friction. Unfortunately, lubrication also often results in adverse effects on tablet characteristics, such as prolonged disintegration, slowed dissolution, and reduced mechanical strength. Therefore, the choice of lubricant and its optimal concentration in a tablet formulation is a critical decision in tablet formulation development to attain low die-wall friction...

13. February 2018

As an essential formulation component for large-scale tablet manufacturing, the lubricant preserves tooling by reducing die-wall friction. Unfortunately, lubrication also often results in adverse effects on tablet characteristics, such as prolonged disintegration, slowed dissolution, and reduced mechanical strength.

30. December 2017

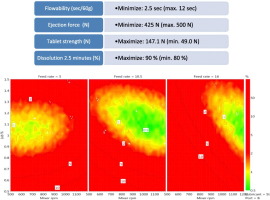

The objective of this study was to devise robust and stable continuous manufacturing process settings, by exploring the design space after an investigation of the lubrication-based parameters influencing the continuous direct compression tableting of high dose paracetamol tablets.

27. December 2017

The aim of this study was to develop a solid dosage form for pediatric application. For this purpose, hyaluronic acid was covalently linked with sulfhydryl groups of cysteine ethyl ester via amide bond formation mediated by carbodiimide.

06. September 2017

Abstract External lubrication is a useful method which reduces the adhesion of powder to punches and dies by spraying lubricants during the tableting process. However, no information is available on whether the tablets prepared using an external lubrication system can be applicable for a film coating process. In this study, we evaluated the adhesion force of the film coating layer to the surface of tablets prepared using an external lubrication method, compared with those prepared using...

05. September 2017

Abstract External lubrication is a useful method which reduces the adhesion of powder to punches and dies by spraying lubricants during the tableting process. However, no information is available on whether the tablets prepared using an external lubrication system can be applicable for a film coating process. In this study, we evaluated the adhesion force of the film coating layer to the surface of tablets prepared using an external lubrication method, compared with those prepared using...

09. March 2016

Abstract: Lubrication plays a key role in successful manufacturing of pharmaceutical solid dosage forms; lubricants are essential ingredients in robust formulations to achieve this. Although many failures in pharmaceutical manufacturing operations are caused by issues related to lubrication, in general, lubricants do not gain adequate attention in the development of pharmaceutical formulations. In this paper, the fundamental background on lubrication is introduced, in which the relationships...