- Home

- Blog

- News

- Basics

- Sources

- Agencies, Regulatory & Organisations

- CERSI Excipients Browser

- Excipient Report

- Excipient DMF List

- EXCiPACT Certified Companies

- Excipient Documentation

- Excipient EINECS Numbers

- Excipient E-Numbers

- FDA Inactive Ingredient List

- FDA GRAS Substances (SCOGS) Database

- IPEC Americas

- USP - U.S. Pharmacopeia

- Definitions

- Whitepapers / Publications

- Supplier

- Services

- Media

- Events

- 1st pharmaexcipients Poster Award

- Event Calendar

- Events featured by pharma-excipients

- 4th Annual Formulation & Drug Delivery Congress

- DDF Summit

- ExcipientFest Americas

- ExcipientFest Asia

- Global CompliancePanel

- International Conference and Exhibition on Pharmaceutics & Novel Drug Delivery Systems

- Formulation & Drug Delivery USA Congress

- Laboratory Medicine 2018

- Making Pharmaceuticals Europe

- Making Pharmaceuticals Exhibition

- Pharma Integrates

- PharmaExcipients China @CPhI China

- TTC Technology Training Center

- Jobs

- Online Sourcing

- Contact

07. July 2018

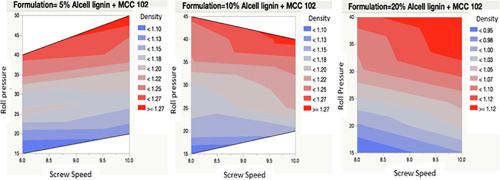

In this study, a process map was developed in an effort to improve the understanding of dry granulation of pharmaceutical excipients by roll compaction process, and to implement the quality-by-design (QbD) approach. Through development of the process map, a correlation was made between the critical process parameters (roll pressure, screw speed), and critical quality attributes (density of ribbons and granule size). This method reduces development time, quantity of materials required and cost....

20. May 2018

The influence of particle morphology and size of alpha-lactose monohydrate on dry granules and tablets was studied. Four different morphologies were investigated: Two grades of primary crystals, which differed in their particle size and structure (compact crystals vs. agglomerates). The materials were roll compacted at different specific compaction forces and changes in the particle size distribution and the specific surface area were measured. Afterwards two fractions of granules were pressed...

06. April 2017

Abstract With increasing importance of continuous manufacturing, the interest in integrating dry granulation into a continuous manufacturing line is growing. Residence time distribution measurements are of importance as they provide information about duration of materials within the process. These data enable traceability and are highly beneficial for developing control strategies. A digital image analysis system was used to determine the residence time distribution of two materials with...

14. February 2017

Abstract Dry granulation using roll compaction is a typical unit operation for producing solid dosage forms in the pharmaceutical industry. Dry granulation is commonly used if the powder mixture is sensitive to heat and moisture and has poor flow properties. The output of roll compaction is compacted ribbons that exhibit different properties based on the adjusted process parameters. These ribbons are then milled into granules and finally compressed into tablets. The properties of the ribbons...

13. April 2016

In roll compaction, the specific compaction force, the gap width and the roll speed are the most important settings as they have a high impact in the products obtained. However the mechanical properties of the mixture being compacted are also critical. For this reason, a multilevel full factorial design including these parameters as factors plus three repetitions of the center point was performed for microcrystalline cellulose, mannitol and five binary mixtures (15, 30, 50, 70 and 85% MCC)....

15. March 2016

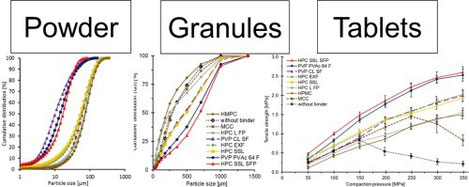

As dry granulation as a continuous process becomes steadily more important, the interest of different materials and their processing is growing. Binders are of high importance as they have to compensate granule hardening, reduce the fines, and ensure adequate tablet tensile strengths. A simple formulation was used for roll compaction/dry granulation with subsequent tableting to produce granules and tablets, containing paracetamol (70% w/w), a filler and a binder (10%). With this formulation...

30. March 2015

Abstract: This study describes the preparation, characterization and performance of a novel excipient for use in oro-dispersible tablets (ODT). The excipient (Cop–CM) consists of chitin and mannitol. The excipient with optimal physicochemical properties was obtained at a chitin: mannitol ratio of 2:8 (w/w) and produced by roll compaction (RC). Differential scanning calorimetry (DSC), Fourier transform-Infrared (FT-IR), X-ray powder diffraction (XRPD) and scanning electron microscope (SEM)...