As dry granulation as a continuous process becomes steadily more important, the interest of different materials and their processing is growing. Binders are of high importance as they have to compensate granule hardening, reduce the fines, and ensure adequate tablet tensile strengths.

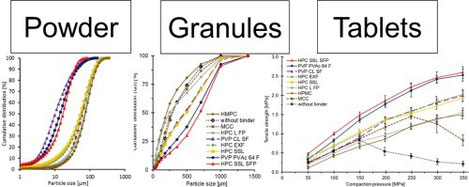

A simple formulation was used for roll compaction/dry granulation with subsequent tableting to produce granules and tablets, containing paracetamol (70% w/w), a filler and a binder (10%). With this formulation other influences were negligible and the influence of the binder was almost isolated. Eight different binders were compared with special attention to raw material properties. Six of them were cellulose based and two of them were based on povidone.

Keywords: Roll compaction/dry granulation; dry binder; particle size; tabletability; granule size Distribution; HPMC, MCC, PVP, HPC