- Home

- Blog

- News

- Basics

- Sources

- Agencies, Regulatory & Organisations

- CERSI Excipients Browser

- Excipient Report

- Excipient DMF List

- EXCiPACT Certified Companies

- Excipient Documentation

- Excipient EINECS Numbers

- Excipient E-Numbers

- FDA Inactive Ingredient List

- FDA GRAS Substances (SCOGS) Database

- IPEC Americas

- USP - U.S. Pharmacopeia

- Definitions

- Whitepapers / Publications

- Supplier

- Services

- Media

- Events

- 1st pharmaexcipients Poster Award

- Event Calendar

- Events featured by pharma-excipients

- 4th Annual Formulation & Drug Delivery Congress

- DDF Summit

- ExcipientFest Americas

- ExcipientFest Asia

- Global CompliancePanel

- International Conference and Exhibition on Pharmaceutics & Novel Drug Delivery Systems

- Formulation & Drug Delivery USA Congress

- Laboratory Medicine 2018

- Making Pharmaceuticals Europe

- Making Pharmaceuticals Exhibition

- Pharma Integrates

- PharmaExcipients China @CPhI China

- TTC Technology Training Center

- Jobs

- Online Sourcing

- Contact

21. July 2018

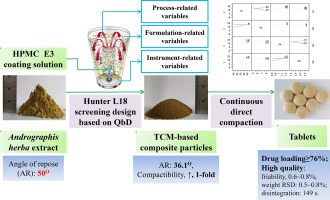

The Andrographis herba extract (AHE), a traditional Chinese medicine (TCM), was developed to directly compactible powders by fluid bed coating with 6% to 12% hydroxypropyl methylcellulose (HPMC). The process-, instrument-, and formulation-related variables of the coating process were simultaneously optimized with the Hunter L18 screening design. Yield (Y1), compactibility (Y2), and angle of repose (Y3) were measured as the responses. The optimized variables were 50 °C for inlet air...

07. July 2018

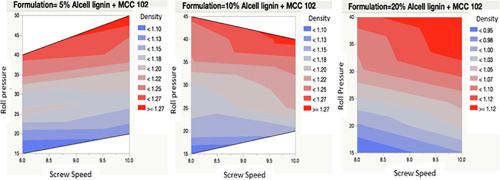

In this study, a process map was developed in an effort to improve the understanding of dry granulation of pharmaceutical excipients by roll compaction process, and to implement the quality-by-design (QbD) approach. Through development of the process map, a correlation was made between the critical process parameters (roll pressure, screw speed), and critical quality attributes (density of ribbons and granule size). This method reduces development time, quantity of materials required and cost....

24. June 2018

Co-processed excipients may enhance functionality and reduce drawbacks of traditional excipients for the manufacture of tablets on a commercial scale. The following study aimed to characterise a range of co-processed excipients that may prove suitable for dispersible tablet formulations prepared by direct compression. Co-processed excipients were lubricated and compressed into 10.5-mm convex tablets using a Phoenix compaction simulator. Compression profiles were generated by varying the...

20. May 2018

The influence of particle morphology and size of alpha-lactose monohydrate on dry granules and tablets was studied. Four different morphologies were investigated: Two grades of primary crystals, which differed in their particle size and structure (compact crystals vs. agglomerates). The materials were roll compacted at different specific compaction forces and changes in the particle size distribution and the specific surface area were measured. Afterwards two fractions of granules were pressed...

15. May 2018

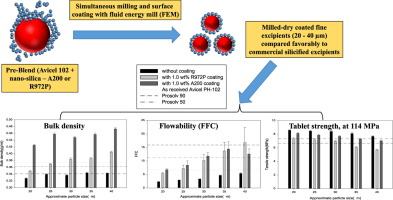

Asolventless process for simultaneously milling and dry coating microcrystalline cellulose (MCC) was investigated for producing fine excipients in five different sizes (∼20, 25, 30, 35, 40µm) havinghigh bulk density (BD), good flow function coefficient (FFC), and excellent compaction. Avicel PH-102, used as the starting material, was milled and coated with two grades of silicas, hydrophobic andhydrophilic (R972P and A200), using a fluid energy mill (FEM). Through judicious selection of the...

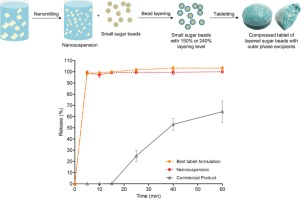

05. September 2017

Abstract There has been limited research done on the downstream processing of nanosuspensions into solid oral dosage forms. This paper demonstrates the bead layering process with a layering level at 150% and 240%, as well as the selection and justification of the outer phase excipients for tabletability and disintegrating properties. In a previous study, an itraconazole nanosuspension stabilised by SDS and HPMC E5 was layered onto sugar beads with coating polymer HPMC VLV. In the current study,...

06. April 2017

Abstract With increasing importance of continuous manufacturing, the interest in integrating dry granulation into a continuous manufacturing line is growing. Residence time distribution measurements are of importance as they provide information about duration of materials within the process. These data enable traceability and are highly beneficial for developing control strategies. A digital image analysis system was used to determine the residence time distribution of two materials with...

04. April 2017

Abstract Ibuprofen is an oral analgesic usually processed by wet granulation. In this manuscript a new roller compaction process for ibuprofen is reported. The low melting point of ibuprofen is a critical point to be considered during processing. Melting of ibuprofen and its posterior solidification leads to a lower soluble form. The hypothesis of this work is that crystallinity of ibuprofen may be a good indicator of the quality for both raw material selection and the granules obtained during...

03. April 2017

Abstract Capping or lamination is an unsolved common problem in tablet manufacturing. Knowledge gaps remain despite an enormous amount of effort made in the past to better understand the tablet capping/lamination phenomenon. Using acetaminophen – containing formulations, we examined the potential use of a compaction simulator as a material-sparing tool to predict capping occurrence under commercial tableting conditions. Systematical analyses of the in-die compaction data led to insight on the...

25. February 2017

Abstract Punch sticking is a frequently occurring problem that challenges successful tablet manufacturing. A mechanistic understanding of the punch sticking phenomenon facilitates the design of effective strategies to solve punch sticking problems of a drug. The first step in this effort is to identify process parameters and particle properties that can profoundly affect sticking performance. This work was aimed at elucidating the key material properties and compaction parameters that influence...