Abstract

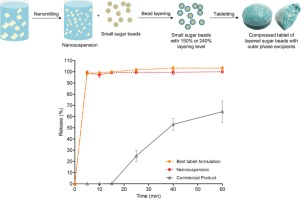

There has been limited research done on the downstream processing of nanosuspensions into solid oral dosage forms. This paper demonstrates the bead layering process with a layering level at 150% and 240%, as well as the selection and justification of the outer phase excipients for tabletability and disintegrating properties. In a previous study, an itraconazole nanosuspension stabilised by SDS and HPMC E5 was layered onto sugar beads with coating polymer HPMC VLV. In the current study, compression studies with these layered beads utilising the small bead size at 150% or 240% layering levels with outer phase cushioning excipients MCC, copovidone or isomalt were performed. Other excipients such as co-compressed crospovidone-PEG 4000; DCP functioning as a disintegrant; and HPC as a binder was also added. Target output variables were achieved with a balance between an adequate tensile strength and fast dissolution rate with a release of 99.0% (± 1.0% SD) within 10 min, which is in accordance with the FDA guidance for dissolution testing. The results show that the compaction of nanosuspension-layered beads is a suitable process for processing an itraconazole nanosuspension into a solid dosage form such as a compacted tablet without compromising on drug release.