Abstract

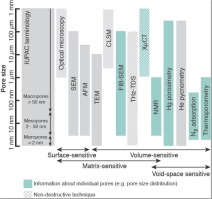

Traditionally, the development of a new solid dosage form is formulation-driven and less focus is put on the design of a specific microstructure for the drug delivery system. However, the compaction process particularly impacts the microstructure, or more precisely, the pore architecture in a pharmaceutical tablet. Besides the formulation, the pore structure is a major contributor to the overall performance of oral solid dosage forms as it directly affects the liquid uptake rate, which is the very first step of the dissolution process. In future, additive manufacturing is a potential game changer to design the inner structures and realise a tailor-made pore structure. In pharmaceutical development the pore structure is most commonly only described by the total porosity of the tablet matrix. Yet it is of great importance to consider other parameters to fully resolve the interplay between microstructure and dosage form performance. Specifically, tortuosity, connectivity, as well as pore shape, size and orientation all impact the flow paths and play an important role in describing the fluid flow in a pharmaceutical tablet. This review presents the key properties of the pore structures in solid dosage forms and it discusses how to measure these properties. In particular, the principles, advantages and limitations of helium pycnometry, mercury porosimetry, terahertz time-domain spectroscopy, nuclear magnetic resonance and X-ray computed microtomography are discussed.

Conclusion

Developing a better understanding of the relationship between the raw materials, process settings, properties of intermediate products and the performance of the finished product requires highly sophisticated techniques to determine key properties of the material at each stage. This cannot be solved by one single technique, but it requires the use of the most appropriate method to determine critical material and quality attributes. We hope that this review has provided an insight into the basic working principles, the capabilities as well as the limitations and pitfalls of each technique.

Recommended for you