- Home

- Blog

- News

- Basics

- Sources

- Agencies, Regulatory & Organisations

- CERSI Excipients Browser

- Excipient Report

- Excipient DMF List

- EXCiPACT Certified Companies

- Excipient Documentation

- Excipient EINECS Numbers

- Excipient E-Numbers

- FDA Inactive Ingredient List

- FDA GRAS Substances (SCOGS) Database

- IPEC Americas

- USP - U.S. Pharmacopeia

- Definitions

- Whitepapers / Publications

- Supplier

- Services

- Media

- Events

- 1st pharmaexcipients Poster Award

- Event Calendar

- Events featured by pharma-excipients

- 4th Annual Formulation & Drug Delivery Congress

- DDF Summit

- ExcipientFest Americas

- ExcipientFest Asia

- Global CompliancePanel

- International Conference and Exhibition on Pharmaceutics & Novel Drug Delivery Systems

- Formulation & Drug Delivery USA Congress

- Laboratory Medicine 2018

- Making Pharmaceuticals Europe

- Making Pharmaceuticals Exhibition

- Pharma Integrates

- PharmaExcipients China @CPhI China

- TTC Technology Training Center

- Jobs

- Online Sourcing

- Contact

30. July 2018

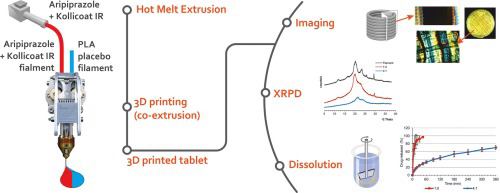

Three-dimensional printing is one of the fastest developing technology withinpharmaceutical field. With many advantages this method can be found as a new dosageform manufacturing technique, however low printing efficiency stays as one of the major limitations. Therefore, the preparation of filaments as a feedstock and printing of the final dosageforms in pharmacies may by the direction of development for this method. Thus, simple dosage and dissolution profile modification seems to be...

06. June 2018

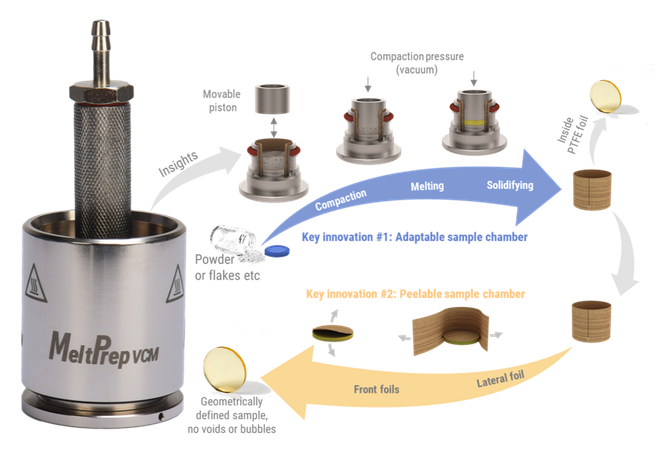

Hot-melt extrusion is well established in the plastics industry and is applied in pharmaceutical application for more than 30 years. In contrast to plastics, pharmaceutical formulation development is more complex as each formulation is unique in terms of compositions of active pharmaceutical ingredients, carrier and additives. Therefore, new innovative solutions are demanded to tackle the pharma specific challenges in formulation development like how to prevent losses with expensive material...

28. May 2018

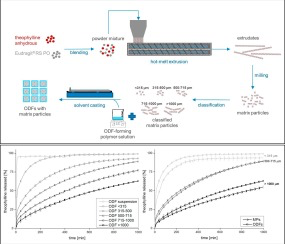

Orodispersible films (ODFs) are an advantageous dosage form to accomplish patient convenience and compliance in oral drug delivery. They provide a number of special application features, such as the ease of administration without water and suitability for patients with swallowing problems. However, this promising dosage form has been limited to immediate release formulations so far. The aim of this study was to develop a thin film produced by solvent casting, which is rapidly disintegrating...

14. May 2018

The objectives of this study were to explore sodium dodecyl sulfate (SDS) and Soluplus on the crystallization inhibition and dissolution of felodipine (FLDP) extrudates by bottom-up and top-down approaches. FLDP extrudates with Soluplus and/or SDS were prepared by hot melt extrusion (HME), and characterized by PLM, DSC and FT-IR. Results indicated that Soluplus inhibited FLDP crystallization and the whole amorphous solid dispersions (ASDs) were binary FLDP-Soluplus (1:3) and ternary...

07. November 2017

Over the last few decades, hot melt extrusion (HME) has emerged as a successful technology for a broad spectrum of applications in the pharmaceutical industry. As indicated by multiple publications and patents, HME is mainly used for the enhancement of solubility and bioavailability of poorly soluble drugs. This review is focused on the recent reports on the solubility enhancement via HME and provides an update for the manufacturing/scaling up aspects of melt extrusion. In addition, drug...

06. November 2017

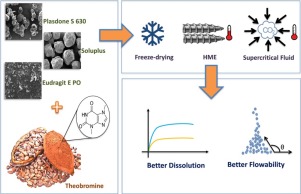

The aim of this study was to improve the pharmaceutical properties of theobromine (TB), particularly its flowability and dissolution rate, by preparing solid dispersions using different technologies (hot melt extrusion—HME, freeze-drying—FD, and supercritical fluid—SF) as well as testing different hydrophilic polymeric matrixes (Eudragit™ E, Plasdone™ S and Soluplus™)

03. November 2017

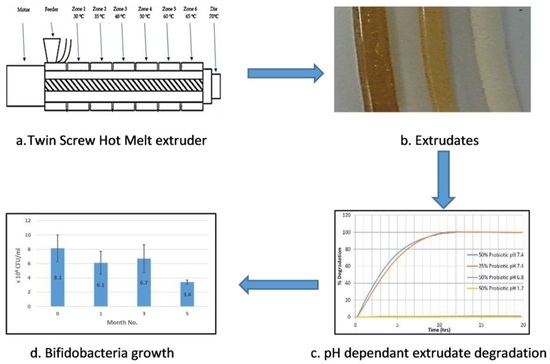

Hot melt extrusion (HME) is considered an efficient technique in developing solid molecular dispersions, and has been demonstrated to provide sustained, modified and targeted drug delivery resulting in improved bioavailability. However, most commercial enteric or pH-responsive polymers are relatively difficult to process or have high Glass Transition Temperature (Tg) values, making their use with temperature-sensitive drugs, probiotics or biologics not viable. Shellac is a natural...

27. September 2017

Many future drug products will be based on innovative manufacturing solutions, which will increase the need for a thorough understanding of the interplay between drug material properties and processability. In this study, hot melt extrusion of a drug-drug mixture with minimal amount of polymeric excipient was investigated.

14. September 2017

Sustained-release formulations have been widely developed to improve the therapeutic performance of drugs, in particular, to increase pharmacological efficacy and reduce side effects.

31. August 2017

This work aimed to obtain an optimized itraconazole (ITZ) solid oral formulation in terms of palatability and dissolution rate by combining different polymers using hot melt extrusion (HME), according to a simplex centroid mixture design. For this, the polymers Plasdone® (PVP/VA), Klucel ELF® (HPC) and Soluplus® (SOL) were processed using a laboratory HME equipment operating without recirculation at constant temperature. Samples were characterized by physicochemical assays, as well as...