- Home

- Blog

- News

- Basics

- Sources

- Agencies, Regulatory & Organisations

- CERSI Excipients Browser

- Excipient Report

- Excipient DMF List

- EXCiPACT Certified Companies

- Excipient Documentation

- Excipient EINECS Numbers

- Excipient E-Numbers

- FDA Inactive Ingredient List

- FDA GRAS Substances (SCOGS) Database

- IPEC Americas

- USP - U.S. Pharmacopeia

- Definitions

- Whitepapers / Publications

- Supplier

- Services

- Media

- Events

- 1st pharmaexcipients Poster Award

- Event Calendar

- Events featured by pharma-excipients

- 4th Annual Formulation & Drug Delivery Congress

- DDF Summit

- ExcipientFest Americas

- ExcipientFest Asia

- Global CompliancePanel

- International Conference and Exhibition on Pharmaceutics & Novel Drug Delivery Systems

- Formulation & Drug Delivery USA Congress

- Laboratory Medicine 2018

- Making Pharmaceuticals Europe

- Making Pharmaceuticals Exhibition

- Pharma Integrates

- PharmaExcipients China @CPhI China

- TTC Technology Training Center

- Jobs

- Online Sourcing

- Contact

05. March 2018

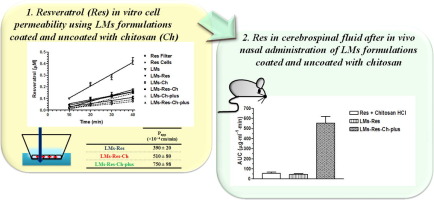

Lipid microparticles (LMs) uncoated or coated with chitosan and containing the neuroprotective polyphenol, resveratrol were developed for its targeting to the brain via nasal administration. The lipid microparticles loaded with resveratrol (LMs-Res) were produced by melt emulsification, using stearic acid as lipid material and phosphatidylcholine as the surfactant.

26. February 2018

Nine common excipients were examined to determine their ability to cause disproportionation of the HCl salt of a a weakly basic compound. The goal was to determine which excipients were problematic and correlate the results to known properties such as surface pH, slurry pH, or molecular structure. Such a correlation enables a general, simple excipient selection process.

26. February 2018

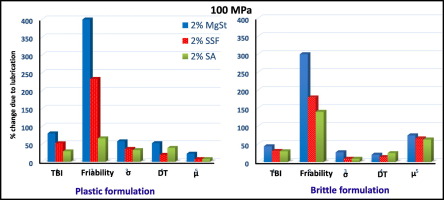

As an essential formulation component for large-scale tablet manufacturing, the lubricant preserves tooling by reducing die-wall friction. Unfortunately, lubrication also often results in adverse effects on tablet characteristics, such as prolonged disintegration, slowed dissolution, and reduced mechanical strength. Therefore, the choice of lubricant and its optimal concentration in a tablet formulation is a critical decision in tablet formulation development to attain low die-wall friction...

13. February 2018

As an essential formulation component for large-scale tablet manufacturing, the lubricant preserves tooling by reducing die-wall friction. Unfortunately, lubrication also often results in adverse effects on tablet characteristics, such as prolonged disintegration, slowed dissolution, and reduced mechanical strength.

30. December 2017

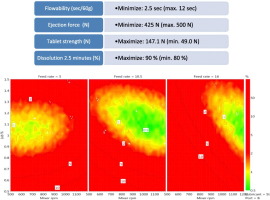

The objective of this study was to devise robust and stable continuous manufacturing process settings, by exploring the design space after an investigation of the lubrication-based parameters influencing the continuous direct compression tableting of high dose paracetamol tablets.

26. November 2017

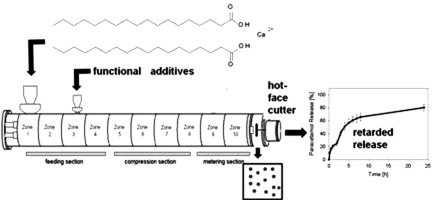

The objective of this study was the development of retarded release pellets using vegetable calcium stearate (CaSt) as a thermoplastic excipient. The matrix carrier was hot melt extruded and pelletized with a hot-strand cutter in a one step continuous process. Vegetable CaSt was extruded at temperatures between 100 and 130 °C, since at these temperatures cutable extrudates with a suitable melt viscosity may be obtained. Pellets with a drug loading of 20% paracetamol released 11.54% of the drug a

01. November 2017

Poor solubility of drugs has always been an issue for formulation scientists thus the search for novel excipients or techniques is an ever-important field in the pharmaceutical developments. Besides the conventional solubilizers or pH adjusters and methods in the past decades particle size reduction is one of the new techniques to enhance the solubility of poorly water soluble drugs.

08. August 2017

We have focused on melt adsorption as manufacture method of wax matrices to control particles size of granules more easily than melt granulation. The purpose of present study was to investigate the possibil- ity of identifying a hydrophobic material with a low melting point, currently used as a meltable binder of melt granulation, to apply as a novel carrier in melt adsorption.