- Home

- Blog

- News

- Basics

- Sources

- Agencies, Regulatory & Organisations

- CERSI Excipients Browser

- Excipient Report

- Excipient DMF List

- EXCiPACT Certified Companies

- Excipient Documentation

- Excipient EINECS Numbers

- Excipient E-Numbers

- FDA Inactive Ingredient List

- FDA GRAS Substances (SCOGS) Database

- IPEC Americas

- USP - U.S. Pharmacopeia

- Definitions

- Whitepapers / Publications

- Supplier

- Services

- Media

- Events

- 1st pharmaexcipients Poster Award

- Event Calendar

- Events featured by pharma-excipients

- 4th Annual Formulation & Drug Delivery Congress

- DDF Summit

- ExcipientFest Americas

- ExcipientFest Asia

- Global CompliancePanel

- International Conference and Exhibition on Pharmaceutics & Novel Drug Delivery Systems

- Formulation & Drug Delivery USA Congress

- Laboratory Medicine 2018

- Making Pharmaceuticals Europe

- Making Pharmaceuticals Exhibition

- Pharma Integrates

- PharmaExcipients China @CPhI China

- TTC Technology Training Center

- Jobs

- Online Sourcing

- Contact

20. August 2018

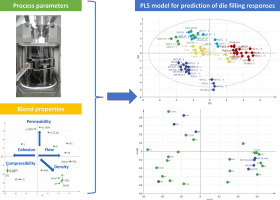

Based on characterization of a wide range of fillers and APIs, thirty divergent blends were composed and subsequently compressed on a rotary tablet press, varying paddle speed and turret speed. The tablet weight variability was determined of 20 grab samples consisting of each 20 tablets. Additionally, the bulk residence time, ejection force, pre-compression displacement, main compression force, die fill fraction and feed frame fill fraction were determined during each run. Multivariate data...

10. August 2018

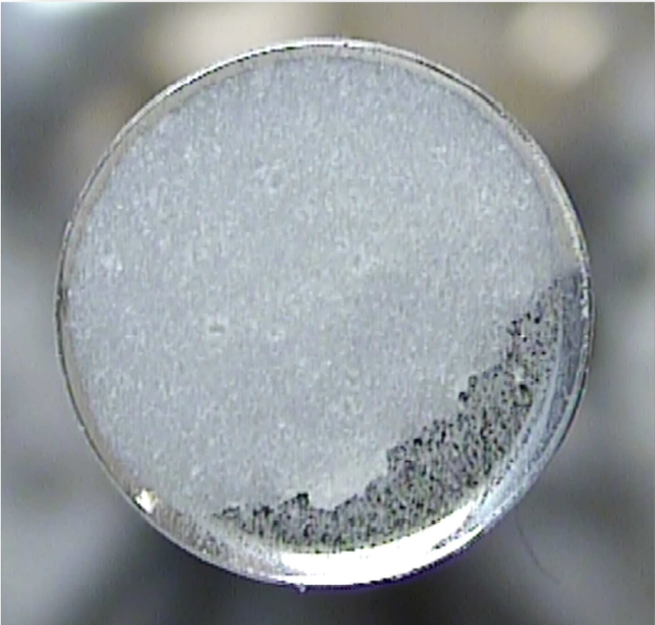

Sticking and picking during tablet manufacture has received increasing interest recently, as it causes tablet defects, downtime in manufacturing, and yield losses. The capricious nature of the problem means that it can appear at any stage of the development cycle, even when it has been deemed as low risk by models, tests, and previous experience. In many cases, the problem manifests when transferring the process from one manufacturing site to another. Site transfers are more common now than in...

04. July 2018

Monoclinic paracetamol (PA) is notorious as a poorly compactible model drug. Polyvinylpyrrolidone (PVP) is a polymer that can act as an effective binder to improve the mechanical properties of PA. It is surprising however that the role of mixing conditions on the physicochemical and mechanical properties of PA–PVP mixtures has not been reported previously. The results of this work showed that PA–PVP mixtures containing 5% (w/w) PVP prepared using high energy mixing conditions had...

09. April 2018

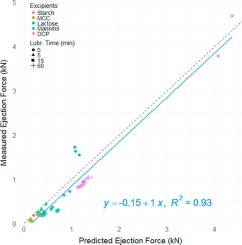

Pharmaceutical powders can exhibit markedly different tablet ejection forces. The purpose of this study is to understand the factors leading to the variability of the tablet ejection force and its sensitivity to lubrication. The study showed that the tablet ejection force is mainly governed by 1) tablet diameter and thickness, 2) compact-die wall friction coefficient, and 3) residual die wall stress upon ejection; the latter was further controlled by the maximum compression pressure, as well as...

06. February 2018

When was the last time you looked at the principles of granulation and tableting? Influence of the granulation process and parameters on the tableting? Continuous high shear Granulation? The current TTC - Technology Training Center - Course: GRANULATION & TABLETING PROCESS Innovative process and tools to achieve the perfect OSD product 17 – 19 April 2018 in Binzen / Germany Gives theoretical and practical Input on theses topics. More Information and Registration

21. December 2017

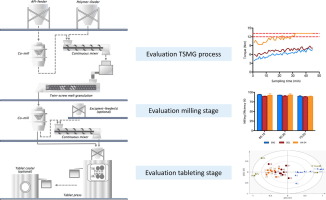

The concept of twin-screw melt granulation (TSMG) has steadily (re)-gained interest in pharmaceutical formulation development as an intermediate step during tablet manufacturing. However, to be considered as a viable processing option for solid oral dosage forms there is a need to understand all critical sources of variability which could affect this granulation technique.

08. November 2017

Co-processing is currently of interest in the generation of high-functionality excipients for tablet formulation. In the present study, comparative analysis of the powder and tableting properties of three co-processed starches prepared by three different methods was carried out. The co-processed excipients consisting of maize starch (90%), acacia gum (7.5%) and colloidal silicon dioxide (2.5%) were prepared by co-dispersion (SAS-CD), co-fusion (SAS-CF) and co-granulation (SAS-CG).

03. October 2017

We report the first multicomponent crystal of desloratadine, an important anti-histamine drug, with a pharmaceutically acceptable coformer of benzoic acid. The single crystal structure analysis revealed that this novel multicomponent crystal is categorized as salt due to the proton transfer from benzoic acid to the desloratadine molecule.

18. August 2017

When tablet formulations are designed, it is necessary to understand “Tableting properties” and to determine the optimum type, grade, and amount of ingredients. “Tableting properties” consist of “Compressibility”, “Compactability”, and “Manufacturability”.

09. August 2017

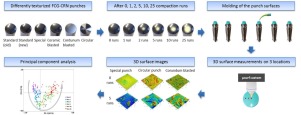

The surface quality of tablets is strongly related to the surface quality of the tablet punch. Therefore, regular control of the punch surfaces is needed to determine the surface properties, the wear status and sticking tendency of the punches