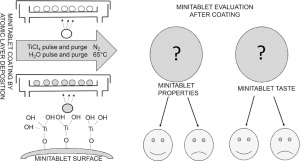

A new coating method via Atomic Layer Deposition (ALD) to achieve an ultrathin coating / nanolayering of mini tablets.

The effects of ALD coating on the tablet characteristics and taste masking were investigated and compared with the established coating method. Minitablets containing bitter tasting denatonium benzoate were coated by ALD using three different TiO2 nanolayer thicknesses (number of deposition cycles). The established coating of minitablets was performed in a laboratory-scale fluidized-bed apparatus using four concentration levels of aqueous Eudragit® E coating polymer. The coated minitablets were studied with respect to the surface morphology, taste masking capacity, in vitro disintegration and dissolution, mechanical properties, and uniformity of content. The ALD thin coating resulted in minimal increase in the dimensions and weight of minitablets in comparison to original tablet cores. Surprisingly, ALD coating with TiO2 nanolayers decreased the mechanical strength, and accelerated the in vitro disintegration of minitablets. Unlike previous studies, the studied levels of TiO2 nanolayers on tablets were also inadequate for effective taste masking. In summary, ALD permits a simple and rapid method for the ultrathin coating (nanolayering) of minitablets, and provides nanoscale-range TiO2 coatings on porous minitablets. More research, however, is needed to clarify its potential in tablet taste masking applications.