Abstract

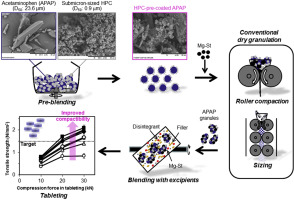

We aimed to investigate the feasibility of our previously proposed method for improving the properties of dry granules by pre-coating of active pharmaceutical ingredients (API) with a submicron-sized binder before conventional roller compaction in lab-scale production. Hydroxypropylcellulose (HPC) and acetaminophen (APAP) were used as the binder and API with low compactibility, respectively. The submicron-sized HPC (HPC-subMP) was obtained using a lab-scale spray dryer; the weight fraction for particle size less than 1 μm was a maximum of approximately 50 wt%. Co-mixing APAP with 5–20 wt% HPC-subMP in the high shear mixer resulted in the APAP particles being pre-coated with HPC-subMP (HPC-coated APAP). The HPC-coated APAP particles were converted into granules following ribbons using roller compactors, mixed with other excipients and compressed as a formulation containing 50% APAP using a single-punch tableting machine. The tablets obtained showed a high tensile strength without significantly prolonged disintegration time; thus, the compactibility of the dry granules could be improved using the HPC-coated APAP. Raman imaging study suggested that the distributional homogeneity of HPC-subMP in the ribbons is an important factor in producing roller-compacted granules suitable for tableting of API with low compactibility without any fundamental changes in materials and manufacturing processes.