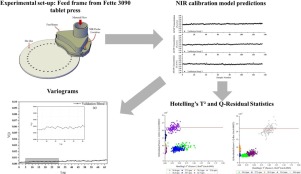

Near infrared (NIR) spectroscopy was used to determine the drug concentration in 3% (w/w) acetaminophen blends within the complex flow regime of the tablet press feed frame just before tablet compaction. NIR spectra also provided valuable information on the powder flow behavior within the feed frame and were used to track when a process enters or leaves the steady state. A partial least squares regression calibration model was developed with powder mixtures that varied from 1.5–4.5% (w/w) by obtaining 135 spectra after steady state for each concentration while the feed frame and die disc operated at 30.5 revolutions per minute (rpm). The calibration model determined drug concentration in validation blends with a root mean square error of prediction and bias below 0.1% (w/w). The robustness of the NIR calibration model was evaluated by determining the effect of variation on the operating conditions (paddle wheel speed and die disc speed) on NIR predictions. This work found that the paddle wheel speed can be increased up to 30% and the die disc speed decrease 10% without affecting NIR predictions. The results demonstrated that paddle wheel speed has a significant effect on the wave powder behavior (frequency and amplitude) but does not have significant effect on the mass hold-up within feed frame. The die disc speed does not affect wave powder behavior but affects significantly the mass hold-up inside the feed frame. This information can be used to reduce the tablet weight variability and ensure that this critical attribute is met.

Conclusions

NIR spectroscopy can be used to evaluate the uniformity of the powder blends with low API concentration and to follow the dynamics or behavior of powder blend inside the feed frame. This study demonstrated that the spectral baseline can be used to track when the powder flow behavior enters or leaves the steady state in the feed frame. The experiments at low paddle wheel speed (24.4 rpm) take longer to reach steady state at the same die disc speed. This study shows that the changes in the spectra baseline shift value are more noticeable when die disc speed changes that when the paddle wheel speed changes.

Variographic analysis demonstrated that the feed frame is a unit that presents low sampling and analytical errors under the conditions of this study. These results demonstrate that the feed frame is a good unit to develop a NIR models to predict API the concentration within the continuous drug manufacturing process.

Variations to disc and wheel speeds were performed to evaluate the predictive capacity of the model. The mixtures that the calibration model is unable to predict present a wide distribution in the Hotelling’s T2. NIR spectroscopy reveals that changes made in the paddle wheel speed significantly affects the wave behavior of the system, when paddle wheel speed decreases the frequency of this movement increases and vice versa, but the mass hold-up

remains constant. Changes in the disc speed affect considerably the mass hold-up within the feed frame, as increase the die disc speed, the mass hold-up decrease, but the wave behavior remains constant.

This work demonstrated that the paddle wheel speed can be increased up to 30% and the die disc speed decrease up to 10% without having a significant effect on the drug content predictions of the NIR calibration model in the feed frame. This information can be used to reduce the variability of tablet weight and ensure that this critical attribute is met and to develop a discrete process control strategy for the die filling process.

Research Paper: https://doi.org/10.1016/j.jpba.2018.03.017