Abstract

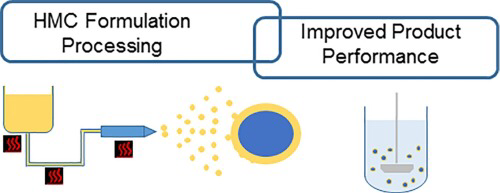

Hot-melt coating (HMC) as a solvent-free technology grants faster and more economic coating processes with reduced risk of dissolving the drug during the process. Moreover, traditional coating equipment can be modified to enable the HMC process. Despite the indubitable advantages and feasibility of the process, HMC is not well-known to pharmaceutical industry and its employment is still limited. The main aspect hindering the widespread application of this technique is the need of materials alternative to the conventional polymeric coatings.

The current work reviews the published HMC formulations and describes the properties that have led to their selection. As these materials are mainly solid lipid excipients, attention should be paid to their crystallization and solid state behavior, and their impact on the performance of coated drug products, particularly on the stable drug release profile.

Although different drug release profiles can be easily tailored, much development work is needed to respond to the unmet requirements of a stable formulation. Ensuring stable solid-state behavior and providing a mechanistic understanding of the macroscopic properties are essential steps towards fulfilling these requirements and establishing of HMC as advanced coating technology for manufacturing of pharmaceutical products.