Over the last two decades, regulatory agencies have demanded better understanding of pharmaceutical products and processes by implementing new technological approaches, such as process

analytical technology (PAT). Process analysers present a key PAT tool, which enables effective process monitoring, and thus improved process control of medicinal product manufacturing. Process

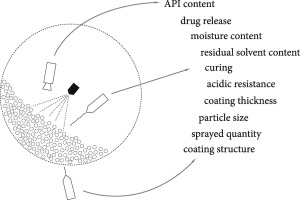

analysers applicable in pharmaceutical coating unit operations are comprehensibly described in the present article. The review is focused on monitoring of solid oral dosage forms during film coating in two most commonly used coating systems, i.e. pan and fluid bed coaters. Brief theoretical background and

critical overview of process analysers used for real-time or near real-time (in-, on-, at- line) monitoring of critical quality attributes of film coated dosage forms are presented. Besides well

recognized spectroscopic methods (NIR and Raman spectroscopy), other techniques, which have made a significant breakthrough in recent years, are discussed (terahertz pulsed imaging (TPI), chord

length distribution (CLD) analysis, and image analysis). Last part of the review is dedicated to novel techniques with high potential to become valuable PAT tools in the future (optical coherence

tomography (OCT), acoustic emission (AE), microwave resonance (MR), and laser induced breakdown spectroscopy (LIBS)).

Overview of PAT process analysers applicable in monitoring of film coating unit operations for manufacturing of solid oral dosage forms

Klemen Korasa⁎, Franc Vrečer

KRKA, tovarna zdravil, d.d., Novo mesto, Šmarješka cesta 6, 8501 Novo mesto, Slovenia University of Ljubljana, Faculty of Pharmacy, Aškerčeva 7, 1000 Ljubljana, Slovenia

KRKA, tovarna zdravil, d.d., Novo mesto, Šmarješka cesta 6, 8501 Novo mesto, Slovenia University of Ljubljana, Faculty of Pharmacy, Aškerčeva 7, 1000 Ljubljana, Slovenia

Recommended for you

- Reformulation of Tablets to resolve sticking & picking issues

- Captisol - modified cyclodextin for improved solubility, stability, bioavailability

- Excipient DMF List